What are the top revenue-generating industrial robot companies in 2022?

Industrial robotics companies are responsible for advancing automation in the robotics industry. Each industrial robotic system must execute functions and commands for material handling, dispensing systems, paint, inspection, palletizing, CNC machining, arc welding, or mechanical joining. The robotic arm is highly proficient at high speeds, keeping its movements accurate. This article will examine the top revenue-generating industrial robot companies and their automation equipment.

Manufacturers choose to invest in an industrial robot brand because of their specific ability to perform complex robotic system tasks. The ability to provide an automation solution for their customers by optimizing sophisticated robotic system movements is necessary for each robotics company in the automation industry. When optimized, these machines can improve a customer’s throughput and ease the workload on their operators.

Main Types of Industrial Robots

Before I start talking about the top industrial robot companies, it is essential to understand what industrial robots are and are not.

Industrial robots are not:

- Collaborative Robots

- Remote-Controlled Drones

- Voice Assistants

- Autonomous Cars

- Software

Below I list the four main types of industrial robots as defined by the International Standards Organization (ISO):

Cartesian Robots:

A cartesian robot will move along three axes in the X, Y, and Z directions. The robot will use one linear actuator for each of its axes. The payloads are usually smaller because of the size and strength of the gripper.

SCARA Robots:

A SCARA (Selective Compliance Assembly Robot Arm) robot will have a small footprint on a single pedestal-mounted robotic arm. SCARA robots are faster and more expensive than cartesian robots.

Delta (Parallel) Robots:

These high-speed robots use kinematic chains connected to the base with an end-effector or gripper. Most delta robot motors drive ridged actuators that can handle high-volume workloads.

Articulated (6-Axis) Robots:

Articulated robots are the most commonly used in the manufacturing and automotive industry. They can handle payloads as large as a vehicle and be as precise as the millimeter. They can be used for many different robot applications, such as; material handling and visual inspection, and even as a welding robot.

How many industrial robots are currently operating around the world?

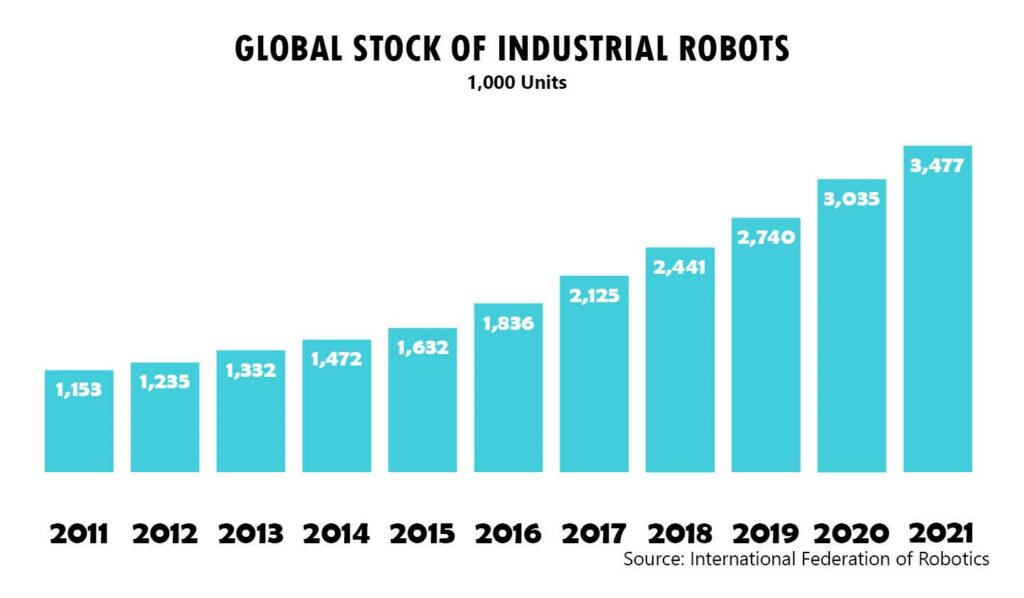

The International Federation of Robotics (IFR) claimed in 2021, approximately 3.5 million industrial robots were operating worldwide. This does not include collaborative robot companies like Universal Robots or robotics companies like Boston Dynamics. This was an overall industrial robot increase of 16% compared to the previous year.

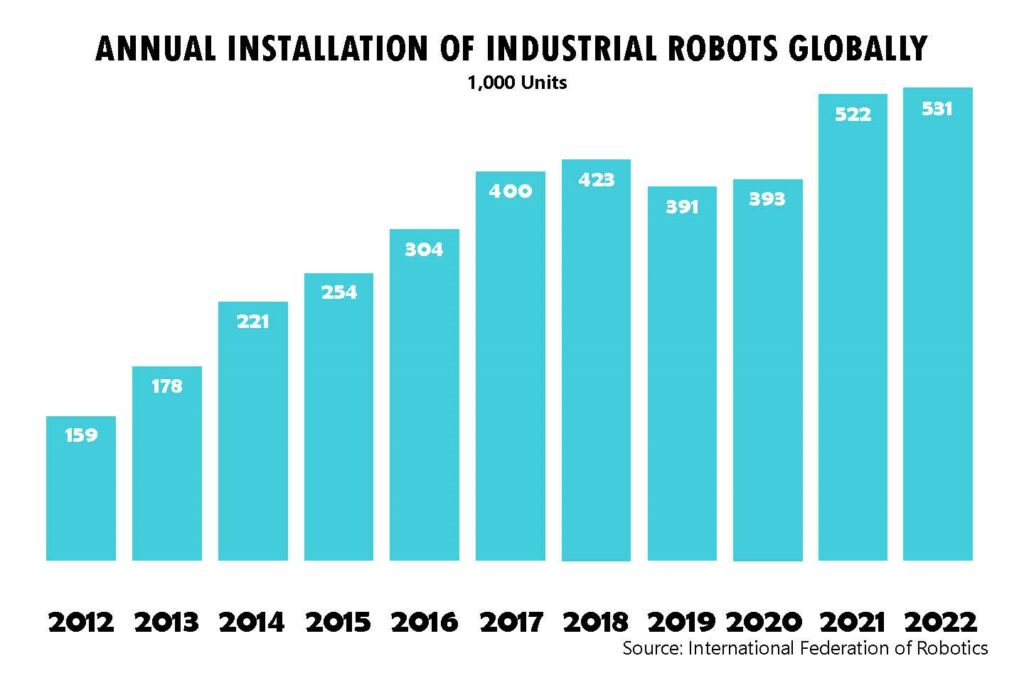

Although the operational use of robots has increased, the trajectory of the number of robots installed has slightly increased from 2021. The average annual robot growth rate will explode to catch up with rising automation demand. In 2025, industrial robot units installed are expected to reach almost 700,000 units annually. [2]

Annual installations of industrial robots in the United States were up 13% from 2021 to 2022. Overall, robot sales in North American manufacturing increased by 12% from 2021 to 2022. In the automotive sector, companies based in Mexico, Canada, and the United States saw industrial robot installations increase by 30% compared to 2021 in 2022 [4].

Top 10 countries that installed industrial robots in 2021:

- China: +268,000

- Japan: +47,000

- United States of America: +35,000

- Republic of Korea: +31,000

- Germany: +23,000

- Italy: +14,000

- Chinese Taipei: +9,600

- France: +5,900

- Mexico: +5,400

- India: +4,900

The Top Revenue-Generating Industrial Robot Companies in 2022:

I have assembled the list of the top robotics companies based on the number of each company’s revenue from their industrial automation systems sales. The global industrial robot market was worth over 50 billion dollars in 2022 [3].

#7 KAWASAKI HEAVY ($1.2B)

Kawasaki Heavy Industries has a large selection of industrial robotic products from pharmaceutical, welding, sealing, cleaning robots, and pick and place. They are one of the global leaders, Kawasaki robotics automation systems have sold over 210,000 industrial robots.

Their United States headquarters is located in Wixom, Michigan.

#6 NACHI ($1.7B)

Nachi Robotic Systems Inc. has a variety of industrial robot models. Nachi offers 52 SCARA and 6-axis articulated robots. They support multiple types of robotic applications, from arc welding, dispensing, material handling, machine tending, palletizing, press tending, spot welding, and many more.

Nachi holds its United States corporate headquarters in Novi, Michigan.

#5 YASKAWA ($3.7B)

Yaskawa Motoman offers 25 different types of industrial robots in its portfolio. These robots include; welding, cutting, assembly, handling, packaging, palletizing, painting, and dispensing. Depending on your application, Motoman robots can have high payloads, rapid movements, and significant work envelopes.

The United States corporate headquarters of Yaskawa America, Inc. is located in Waukegan, Illinois.

#4 KUKA ($3.9B)

KUKA Robotics offers 24 different types of industrial robots. Every KUKA robot in their portfolio has a wide range of options, starting with their delta, cartesian, articulated, and linear robots.

The United States headquarters of KUKA Robotics Corporation is located in Shelby Township, Michigan.

#3 FANUC ($6.5B)

The FANUC Corporation has more than 100 industrial robot models. FANUC offers SCARA, delta, articulated, and even cobots. If a business is looking to optimize a process, FANUC robots will likely have an automated solution because they offer the widest variety of industrial robots.

FANUC holds its United States corporate headquarters in Rochester Hills, Michigan.

#2 ABB LTD ($30.3B)

ABB Robotics offers 26 types of industrial robots. Its industrial automation segment focuses on articulated, delta, SCARA, and paint, which hold payloads anywhere from 3 kg to 800 kg.

ABB’s American headquarters is in Cary, North Carolina.

#1 MITSUBISHI ELECTRIC ($36.6B)

Mitsubishi’s industrial robot revenue was almost double its closest competitor’s. These robots are equipped with high speed and extreme precision. Mitsubishi offers robots with easy-to-use pick and place functions to robots with complex assembly tasks. They also have intelligent packages for vision, sensing, and integration.

The United States headquarters for Mitsubishi Electric Automation, Inc. is located in Vernon Hills, Illinois.

The Industrial Robot Automation Industry:

Although robots have now made it into a growing number of industrial industries, like the food and beverage, and plastic and chemical industries, the highly automated electrical/electronics industry became the most extensive application area for electro-mechanical machines in 2021, followed by the automotive industry.

The robotics industry’s growth trend is primarily driven by rising wage levels that force manufacturers worldwide to replace human labor with machines. Robot programmer jobs are on the rise as well. Asia and Australia lead the way with the most robotic installations (381,000) in 2021, followed by Europe (84,000), then the Americas (51,000). [2] This makes sense as Asia is home to many robot manufacturing companies, including Nachi, Yaskawa Electric Corporation, Fanuc, Kawasaki, and Mitsubishi, requiring robot programming services.

The global control systems and automation market was valued at $172.3 billion in 2022. The industrial robot segment will account for the most significant revenue increase, forecast to grow 12% from 2023 to 2030. Like the industrial robotics market, the factory automation, artificial intelligence, industry 4.0, and controls systems market is forecast to compound an annual growth rate of 10% from 2023 to 2030. This industry comprises various products and services, including relays, switches, sensors, drives, machine vision, control systems, and software development and services. Conglomerates like Siemens, Rockwell Automation, Mitsubishi Electric, Omron Automation, Schneider, and General Electric are significant industrial automation vendors and industry software. [12]

Popular Robotic Companies Revenue in 2022:

Boston Dynamics ($27.6M)

Boston Dynamics is an engineering robotics company that builds robots and simulation software for humans. The company started as a spin-off from MIT (Massachusetts Institute of Technology), where they first developed robots that maneuvered like animals. Organizations like the Marine Corps, Navy, and U.S. Army turn to Boston Dynamics for advice on creating the most advanced robotics on Earth.

The headquarters for Boston Dynamics is located in Waltham, Massachusetts.

Universal Robots ($326M)

Universal Robots are one of the world’s largest collaborative robot (also known as cobot) manufacturers. They have sold over 50,000 cobots and are used in production environments worldwide. Cobots are easier to program and faster to deploy compared to industrial robots.

Universal Robots headquarters is in Boston, Massachusetts.

iRobot ($1.18B)

iRobot is one of the largest robot vacuum cleaning companies in the world. Their autonomous home vacuum cleaners are some of the most popular brands in the robot vacuum space.

The company has its U.S. headquarters in Bedford, Massachusetts.

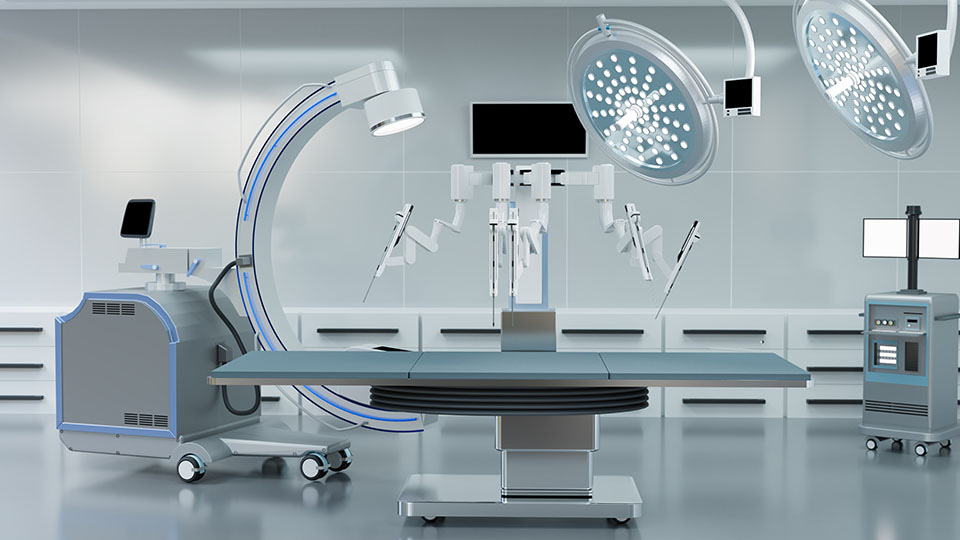

Intuitive Surgical ($6.2B)

Intuitive Surgical, Inc. is a robotics company that develops, manufactures, and markets robotic products in the healthcare industry. Their medical robots perform minimally invasive surgery that is more precise than using the hands of a doctor.

The headquarters for Intuitive Surgical is located in Sunnyvale, California.

Rockwell Automation ($7.76B)

Rockwell Automation, Inc. provides its main products for industrial automation and digital transformation technologies. The organization is structured into three major brands: FactoryTalk software, Allen-Bradley PLCs, and LifecycleIQ Services.

Rockwell Automation holds its headquarters in Milwaukee, Wisconsin.

Siemens AG ($78.03B)

Siemens is a technology company focusing on industrial, transportation, healthcare, and infrastructure. They are one of the largest industrial manufacturing companies in the world. Their key focus is on automation, digitalization, and industrialization.

The United States headquarters for Siemens is located in Washington, D.C.

Data Resources:

- [1] https://www.iso.org/home.html

- [2] https://ifr.org/downloads/press2018/2022_WR_show_version.pdf

- [3]https://ifr.org/downloads/press2018/2023_05_23_IFR_Executive_Roundtable_Detroit_Automate.pdf

- [4]https://ifr.org/ifr-press-releases/news/robot-sales-in-north-american-manufacturing-up-12-percent

- [5] https://www.macrotrends.net/stocks/charts/KWHIY/kawasaki-heavy-industries/revenue

- [6] https://www.dnb.com/business-directory/company-profiles.nachi-fujikoshi_corp.b878b7625acedf89b9196234c6b2f3a0.html

- [7] https://www.dnb.com/business-directory/company-profiles.yaskawa_electric_corporation.86811e6a946fc05608e8b1b213a35947.html

- [8] https://www.kuka.com/en-us/company/press/news/2023/04/kuka-financial-figures-2022

- [9] https://www.macrotrends.net/stocks/charts/FANUY/fanuc/revenue

- [10]https://companiesmarketcap.com/abb/revenue/#:~:text=According%20to%20ABB’s%20latest%20financial,sale%20of%20goods%20or%20services

- [11] https://companiesmarketcap.com/mitsubishi-electric/revenue/

- [12] https://www.grandviewresearch.com/industry-analysis/industrial-automation-market

- [13] https://www.zippia.com/boston-dynamics-careers-1206628/revenue/

- [14] https://www.universal-robots.com/about-universal-robots/news-centre/universal-robots-reports-record-revenue-despite-global-uncertainty/

- [15] https://investor.irobot.com/news-releases/news-release-details/irobot-reports-fourth-quarter-and-full-year-2022-financial#:~:text=Full%2Dyear%202022%20revenue%20of,from%20%241%2C565.0%20million%20in%202021

- [16] https://isrg.intuitive.com/news-releases/news-release-details/intuitive-announces-preliminary-fourth-quarter-and-full-year-2

- [17] Rockwell Automation Revenue 2010-2023 | ROK

- [18] Siemens AG Revenue 2010-2022 | SIEGY