The Top 5 Reasons Why Companies Have Inefficient Production Lines

Productivity analysis can benefit manufacturers no matter the industry or size of the company. This is particularly true for production lines that scrap materials, have slow cycle times, or use extra energy during the assembly line process. These things could go unnoticed and affect the company’s success.

Manufacturers can stay competitive in their respective industries by understanding their production inefficiency and knowing how to achieve peak production efficiency. In this article, I will teach people how to improve production efficiency within their manufacturing company.

What can a company do about production inefficiencies?

We must define production efficiency to help explain the definition of production inefficiency.

Production Efficiency Meaning.

Efficient production or production efficiency is when the assembly line can produce the maximum amount of product that can be produced at its peak. This is generally accomplished when the machines and equipment on an assembly line are running at 100%, without any delays or pauses during manufacturing.

Inefficient Production Meaning.

Production inefficiency refers to the waste of energy or mechanical resources that cause assembly line issues that prevent the production line from reaching its full potential.

Each company may qualify its efficiency differently, but the same general guidelines can be used to improve its production processes. Most of the time, inefficient production lines result from improper production planning. Determining where an assembly line could be more efficient can also be a challenging task, especially with complex engineering processes that may be in place. Below I will list how to plan appropriately so your company does not run into inefficiency issues.

The 5 reasons why companies have inefficiencies in their production lines.

1. The company’s personnel are not properly trained.

This is generally the most important and challenging to change within an organization. The importance of staff being knowledgeable in the field in which the product is being made is extremely important to the company’s overall productivity.

If the business is struggling to train its employees, consider hiring a training service group to help train the employees in the facility’s processes and types of automation. For companies that need to hire temporary contract help with experienced and qualified technicians, JOINER Services can assist in these types of contract engineering services.

If the employees need to learn new manufacturing processes, sometimes the best thing to do is to train the critical stakeholders of that process or area. Training personnel can customize a plan that meets any organization’s needs to allow employees to resolve technical problems independently.

It is a scientific fact that employees feel more connected to their job tasks when they understand their roles and how to perform. When the employees are part of the company’s building success, they will be more motivated to do their best work and improve the workplace environment around them.

2. They lack sustainable manufacturing methods.

Unsustainable factories will create waste throughout the entire production process. Not only is it better for the environment if the line is more efficient, but it also helps reduce scrap, electrical, labor, and capital equipment costs, all while increasing production output.

The companies often the best with lean manufacturing usually know more about 5S and kaizen manufacturing processes. These techniques can reduce waste and help create a more productive manufacturing process.

Partnering with an organization that can help create a more sustainable production system through all build phases of a project will result in a flexible production line efficiency that is effective and reduces energy costs.

3. No scheduled down-time in the manufacturing plan.

Automation downtime can be a significant cause of production line inefficiencies. Automated lines will run at 100% production capacity when the automation equipment runs without fault.

Having planned downtime with a scheduled preventative maintenance plan can have significant advantages, such as reducing maintenance schedules for equipment, repairs, and proper cleaning. Unscheduled downtime can be highly costly to manufacturers, so having an hourly, daily, and monthly schedule for maintenance is necessary.

For specific manufacturing processes, it can cost thousands of dollars per minute to have unscheduled downtime. The company can save money and increase production efficiency by making changes to their production line by adding scheduled down.

4. The machines are not properly maintained.

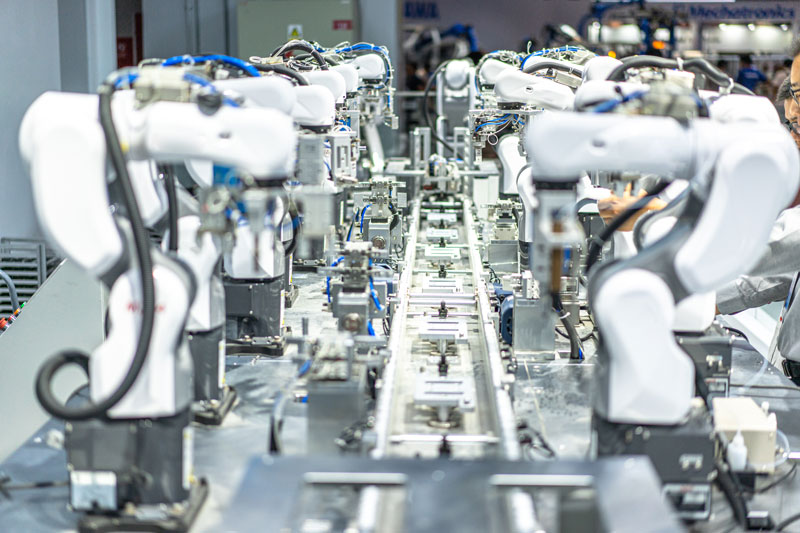

Industrial robots and other manufacturing equipment must be in top condition to operate as efficiently as possible. Keeping a machine running smoothly when appropriately maintained and in good running condition is the easiest.

It should be considered to send the equipment in for reconditioning or refurbishing if the technicians notice that the machine uses more energy, its operations are slowing down, or they notice visible defects. By replacing worn parts and cleaning out grease, dust, metal shavings, or other particles, equipment that has been refurbished or reconditioned will have a much longer life cycle.

Sometimes replacing tooling, machines, or equipment is more economical than repairing or reconditioning. However, buying new or used industrial robots and equipment from a reputable supplier who can provide a warranty on this industrial equipment is very important.

5. The quality of the products being manufactured.

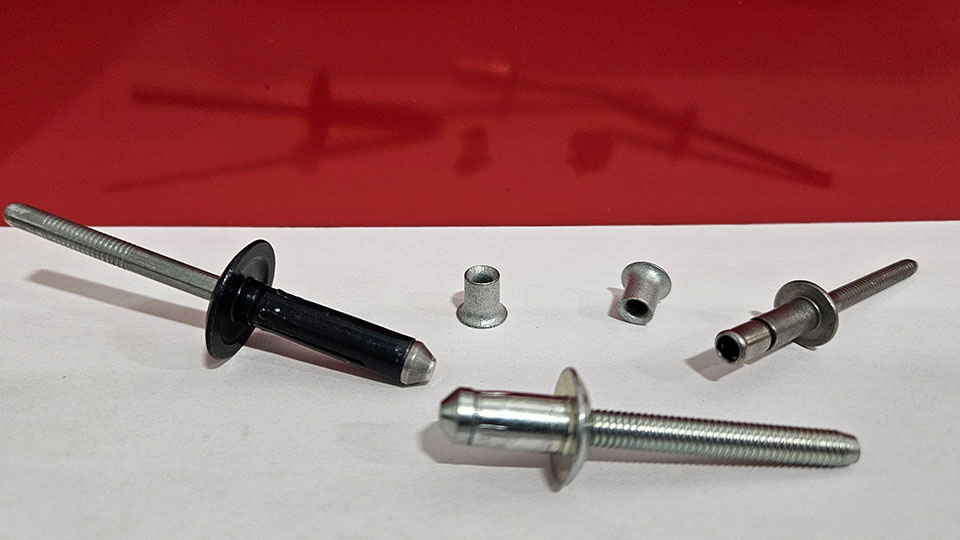

Using low-quality materials during manufacturing can lead to more waste and create products that do not meet standards or specifications and should be scrapped. These low-quality products can cause customer dissatisfaction, damaging a company’s reputation with its customers.

Initial prototyping with quality material is a great way to optimize product design and ensure the best product for the customer. In addition, this will decrease the risk of losing customers to a competitor and help reduce scrap in the production line.

I recommend the company find a local supplier to provide consistent materials for the production line. Performing quality checks on the incoming materials should be a part of the delivery inspection performed by the company’s quality team. All incoming materials should also have a material data specification sheet provided by the supplier.

Find the inefficiencies in your production line!

If a business wants to be competitive in a local and especially the global market, it must boost its production efficiency to be more competitive.

The company will grow by being diligent with its productivity analysis. This will allow the company to increase its revenue and save on other resources.

To improve the company’s productivity, check the assembly line for any of the inefficiency causes mentioned in this article. These are some of the most common reasons for inefficient production lines in factories, so look through the factory to see if any areas can be improved for greater productivity.

If you can identify production inefficiencies, you can fix them!

How can a company improve production efficiency?

Below I describe the 10 ways companies can improve production efficiency. These suggestions may vary depending on your facility’s industry, product, and processes. Conducting a thorough automation analysis of your operations and involving your whole team when identifying and implementing changes to improve assembly line efficiency is essential.

- Standardize The Processes: Establishing standardized work procedures and instructions helps to streamline operations and reduce variations in production. Clearly defining the steps, tools, and techniques required for each task helps improve efficiency and minimize errors.

- Optimize The Workflow: Analyze the layout and flow of the assembly line to identify any bottlenecks or areas of inefficiency. Rearranging workstations, materials, or equipment can create a more streamlined and efficient workflow by reducing unnecessary movements and improving the line’s overall productivity.

- Use Lean Manufacturing Principles: Implementing lean manufacturing principles, such as just-in-time (JIT) inventory management and continuous improvement, can enhance the production line’s efficiency. Minimize inventory levels, reduce scrap, and involve employees in identifying and implementing process improvement.

- Add Automation: Evaluate opportunities to introduce automation and technology into the assembly line. Automated machinery, industrial robotics, collaborative robots, programmable logic controllers (PLCs), and computer systems can help ramp up production, improve precision, remove repetitive tasks, and remove humans from dangerous or more labor-intensive tasks.

- Upskill The Workforce: Invest in training programs to upskill your workforce with new skills and knowledge. Well-trained employees are more efficient and can identify opportunities for improvement. A culture of knowledgeable employees engaged in what they do will boost the company morale, leading to more teamwork and better productivity.

- Time Performance Studies: Conduct time studies to analyze the duration of each task or operation on the assembly line. Identify areas where there are bottlenecks in the line or inefficiencies that can be addressed to reduce cycle times and improve overall process flow.

- Workforce Development: Offer ongoing skill development opportunities to your assembly line workers. Please provide them with the necessary knowledge and skills to perform their tasks efficiently. I have noticed that most people want and are willing to learn new things, especially if it is automation related. Providing weekly, monthly, or quarterly skill, operations, or quality development programs with your workforce will improve productivity and quality output.

- More Quality Control Measures: Implement robust quality control measures at various stages of the assembly line. To improve manufacturing efficiency, incorporate inspection checkpoints, establish preventative maintenance schedules, and develop quality assurance protocols with quality control tools to detect and prevent defects early. This helps reduce rework, scrap, and overall waste while improving the product’s overall quality.

- Workplace Organization: Try these 3 things to improve workplace organization. Adopt the principles of the 5S (Sort, Set in Order, Shine, Standardize, Sustain) methodology to create an organized and efficient workspace for the employees. Maintain a clutter-free environment, and ensure that tools and materials are easily accessible for the employees. Use visual management systems to start and sustain cleanliness in the workspace while informing workers of the standards that help prevent workplace hazards.

- Continuous Process Monitoring: Utilize data collection and analysis tools to monitor key performance indicators (KPIs) related to production output, cycle times, defect rates, and other relevant metrics to the assembly line process. Analyzing this data daily can help identify trends and areas for improvement and provide insights into other optimization opportunities.

These suggestions are general and may need to be customized based on your assembly line’s requirements and challenges. Still, if you engage with your team by doing the 10 items I have listed above, you will significantly contribute to achieving productivity enhancements.