Although automating a manufacturing facility can be difficult, automating production lines can be very successful if the business leadership has the right mindset and the company can purchase the correct tools or equipment.

The reasons why companies fail when implementing industrial automation:

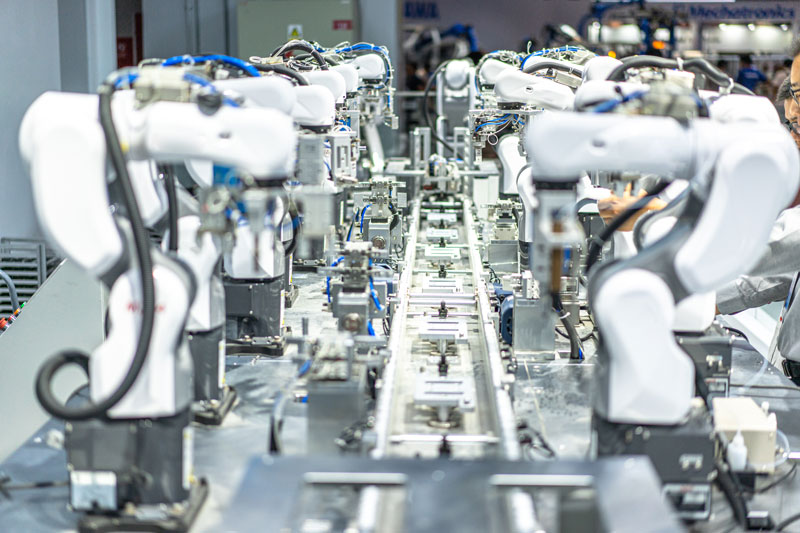

Companies without automation will be left behind as Industry 4.0 grows. Small and medium-sized companies are using robotic systems to improve their manufacturing processes; however, choosing automation should be done precisely and carefully thought through. A business can end up with costly equipment that doesn’t help it or if industrial robots and equipment are added to the facility without taking the proper steps to integrate them.

The top 8 reasons why companies fail with industrial automation:

Below I list the top reasons a business might not be properly automating and suggest how to fix these automating issues correctly.

#1 Automation knowledge is not well-known within the organization.

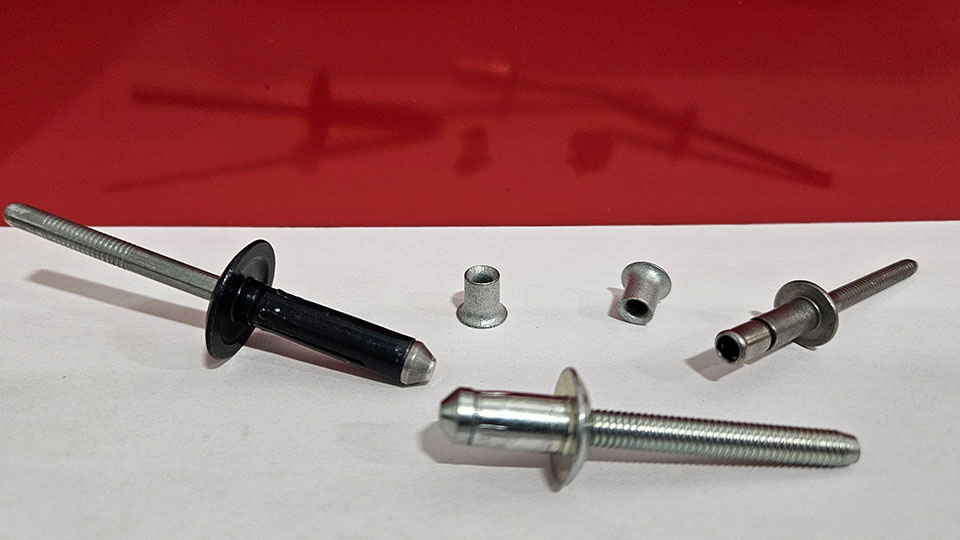

Automation does not just include industrial robots but other components of the automation process.

Many components together must be used to automate a process, such as:

- Motor Drives and Controls

- Process Monitoring

- Fixtures / Tooling

- Solenoid Valves

- Sensors and or Cameras

- Conveyors

- Electrical Wiring

- Clamping of Parts

- Safety Circuits, Switches, and Emergency Stops

- Discrete and Analog – Inputs/Outputs

- Servo Drives

- Human Machine Interface (HMI) Units

- Industrial Robots or Collaborative Robots

Every component I listed above has a unique benefit for running a production line correctly. Most automation lines will use all or most of the components listed above. To properly automate, the organization must learn about industrial robots and the equipment used in industrial manufacturing.

Businesses must use every bit of information to make better decisions about industrial automation in their manufacturing process. The organization may contact contract businesses experienced in industrial automation and installation experience for guidance with the overall automation project.

#2 Staffing issues.

Companies often try to automate to resolve staffing issues, but this can also create more staffing issues. As these companies look to embrace more advanced technologies to manufacture products, it can be challenging to find new employees with experience or the technical skills to work with these automation systems. Many companies lack skilled engineers with sufficient expertise in industrial automation, so finding new engineering talent can be extremely challenging, depending on the company’s location.

Many experts believe the manufacturing industry’s skills gap will increase to 2.1 million vacant positions by 2030. Many companies are looking to engineering consulting firms to help support some of these labor shortages by providing contract labor support until they can fill the open automation jobs. Companies can look internally rather than using external engineering service companies for labor support. These companies try to reskill or upskill their internal workforce. Due to these massive labor shortages, this can be implemented faster and in a more cost-effective way than hiring new employees. Providing new career advancement opportunities will also improve worker retention within the company.

#3 Design road maps were not performed.

The company needs to create a plan to identify which processes in the manufacturing workflow are suitable for automation. They must map out the assembly flow and which areas should be changed from manual to automated.

This design map visually illustrates the company’s future automated manufacturing process. This visual illustration should map out an overview of each task performed during each station of the automated assembly line.

These design maps will help an organization find any inefficiencies in the stations and can help optimize the assembly line.

The 4 Types of Design Models:

- Fixed Automation: In this configuration, the equipment and tooling are fixed to produce one product at high volumes.

- Flexible Automation: This configuration can produce batch runs of multiple products that are computer controlled for low to medium volumes.

- Programmable Automation: This configuration can automatically change with specific programmed codes and produce low- or high-volume products.

- Integrated Automation: This configuration combines the system with computers and other control processes that can produce high volumes of multiple parts.

Once a design model is selected, it is time to start developing the automation plan. Automation should focus on cycle time, repetitive tasks, or tasks that may be too dangerous for humans and build the processes around these stations.

#4 The company’s targets are not correctly communicated.

To have a functional robotic production line, knowing the automation’s end goals is essential. Is the company only automating to keep up with its competitors in the industry or because they believe automating is more manageable than manual labor? This thinking will result in a lack of foresight to recognize what should and should not be automated in a facility.

Here is a list of standard questions every company should ask before investing in automation:

- Can the process reduce the overall cycle time of the product while increasing the throughput of the product?

- Does the current process have any repetitive manual labor tasks?

- Can any processes be standardized to help automation?

- Is the current process putting humans in potentially harmful situations?

- Can customized fixtures and tooling be built for an automated system?

- Will this process help reduce scrap?

If the business can answer yes to all the goals listed above, then this assembly process is a candidate for automation.

#5 The production line does not include enough manual labor.

Automation is only possible with the help of humans working together with robots. Automation allows us to improve large-scale repetitive processes but may be one of many labor solutions.

Automation is an excellent tool for businesses, as it can record, store, and provide live data about the manufacturing process. In addition, it can help identify where resources are being wasted and which tasks are underperforming. It can also alert operators and maintenance of any errors or faults, so they can quickly fix any issues.

Having a group of managers who monitor the status of the assembly line data is a critical role in any facility. They can identify a daily top 10 faults or occurrences list. Hence, engineering and maintenance technicians know where to fix issues, and the production line runs more smoothly, saving the business time and money.

# 6 High equipment cost.

The most common issue many companies face with automation is the high equipment cost. Industrial robots come with significant upfront costs, and many companies are very optimistic about their return on investment (ROI). Setting realistic automation expectations is the best thing to remember when implementing a new system.

Companies must understand that industrial robots often require additional infrastructure, like sensors, safety barriers, and conveyor systems, that can raise the installation price. Some experts believe that the actual ROI is usually around three times the industrial robot’s price tag cost, plus the labor cost of the installation.

After an organization sets a more realistic expectation to guide its decisions, it can take other steps to lower costs. Many companies are now starting to purchase refurbished or used industrial robots. This cuts much of the initial cost of the industrial robot while still providing the same equipment quality as a new system and having a quicker ROI than purchasing brand-new robots.

#7 The system is not optimized.

To have a successful automated process, it may be surprising that having a production line solely operated by industrial robots is not critical. It is critical that the production line must flow with each process working for the next station while the total allowable cycle time of the station is not interrupted.

Streamlining the automated stations is the key to a successful assembly line process. Automating means having a rapidly flowing production process with robot cycle time optimized with the stations working together as a single unit.

It is essential, especially during start-up operations, that robot paths and PLC logic are optimized at the beginning of the installation. It is easier to make corrections and changes earlier than after the system is ready in fully automatic mode.

Take the time to learn the movements, watch the automated system, and note areas where improvements can be made. Often this can take thousands of cycles to notice where changes can occur.

#8 The organization does not understand automation.

Automation can only succeed if the team or organization understands the essential functions of the automated equipment. Automation can be challenging if anyone is unclear about the tasks or needs help understanding the relationship with the robots in the production area.

It is essential to put individuals in critical roles within the organization who have experience or an understanding of process automation so they can pass on the critical automation knowledge to the rest of the team.

It is also vital to share the latest automated process changes with the organization to fully integrate robotics into the company, especially if this is the first automated assembly line.

In conclusion, the reasons companies fail at implementing industrial automation due to factors such as inadequate planning, lack of automation knowledge, staffing issues, high equipment costs, not enough human intervention, and insufficient process monitoring. Overcoming these challenges requires a strategic approach with careful planning, effective management, investment in employee training, realistic ROI projections, and a commitment to continuous learning. By addressing these factors, manufacturing companies can increase their chances of successful robotic process automation implementation and reap the numerous benefits of this transformative technology in the industrial manufacturing industry.

Don’t make automation mistakes. Make automation support easy!

Industrial automation is becoming more common, and as intelligent automation technology advances, it is easier to automate. Engineering service companies like JOINER Services can help improve and build automation processes through their talented contract engineers and succeed from the start of your project.

Data Resources:

- [1] https://www.i-scoop.eu/industry-4-0/

- [2] https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-diversity.html