It is hard to imagine a manufacturing factory without any automation, but many manufacturing facilities still need to be convinced to purchase industrial automation. Automation uses computer software systems with industrial robots to automate tasks previously performed with manual labor. These industrial automation systems control the industrial equipment, significantly reducing operator involvement and oversight of machinery.

Defining industrial automation:

Industrial automation uses software and hardware equipment to manage industrial machinery and processes to increase productivity and quality while reducing labor costs. This includes many pieces of equipment like; control systems, PLCs, industrial robots, sensors, and actuators. The system’s data is then collected and stored as real-time data that can be used to track the automated system’s productivity, fault logs, cycle time, and downtime history.

So, what are industrial automation systems?

Most industrial automation systems are composed of feedback loops or sensory programs that adjust operating conditions automatically to achieve desired values. These programs are based on real-time data collection. Digitalization of manufacturing has led to significant advances in the technology used in industrial automation solutions. In particular, the Industrial Internet of Things (IIoT) opens up new opportunities for companies to use automation solutions.

Why is industrial automation essential in manufacturing?

Industrial automation plays a vital role in manufacturing today because of its potential to significantly enhance productivity and quality. Automated systems, which can operate non-stop, without breaks, significantly accelerate the production process and easily increase the output capabilities verse any human workforce. These systems can ensure a level of consistency and, depending on the task, can have better quality products compared to manual labor. Automation also offers the advantage of increased safety, as it can perform tasks that put workers in danger, such as handling hazardous materials or lifting heavy objects repetitively.

The leading case for automation is the financial implications and how it can help a company with labor shortages continue to grow. While the initial investment in automation equipment and its technology can be significant, the long-term return on investment (ROI) through decreased labor costs, waste reduction, and optimizing assembly efficiency makes it a long-term, cost-effective decision. The flexibility of many automated systems allows for quick change-overs, which accommodates changing production needs without significant downtime.

Industrial automation also aids in real-time data monitoring and enhancing the visibility of potential production issues. Automation is crucial for industry competitiveness, where inefficient production lines that use a manual process will be left behind. Automation processes can take over simple and repetitive tasks, freeing the human workforce to be upskilled from an operator to a more technical role within an organization.

How do industrial automation systems work?

For industrial automation systems to work, they must use a relatively complex four-step process using different automation hardware and software. The system’s goal is to replace human intervention and make the production line more efficient while becoming safer for the workers using the system. Below I list how this process works.

- Step 1: Gather Data – Various sensors and monitoring systems gather input from the equipment. This data includes temperatures, pressures, part present switches, and other measurements sent to a central control system.

- Step 2: Process Data – The control system then processes that data, often with high-tech controller software, and makes decisions based on preprogrammed parameters. This can be simple tasks like if the sensor is “on,” then the part is present, to very complex tasks, like if Robot A is at Position X, it is safe for Robot B to now move.

- Step 3: Output Actions – The control system can send commands to machines, conveyors, or industrial robots to perform specific actions based on the status of the processed data. This can be starting or stopping the assembly line, increasing or decreasing speed, or even performing a changeover throughout the factory. For example, if Button X is pressed, change over the whole line from running Product A and start running Product B.

- Step 4: Feedback Loop – Information gathered from the results of these output actions is also sent back to the central control system, which creates a feedback loop. This allows the system to adjust and improve performance continuously without human intervention.

Introducing these advanced technologies into industrial automation systems, such as the Internet of Things (IoT) and machine learning, has further enhanced the overall package of automated systems capabilities. These newer technologies allow machines to learn from the gathered data, make predictions through the automated process, then perform actions from the data autonomously, creating what many call a “Smart Factory” in the new world of Industry 4.0.

Examples of Industrial Automation:

What is industrial automation in your business? Below are examples of industrial automation, systems, equipment, or process automation.

- Material Handling Systems

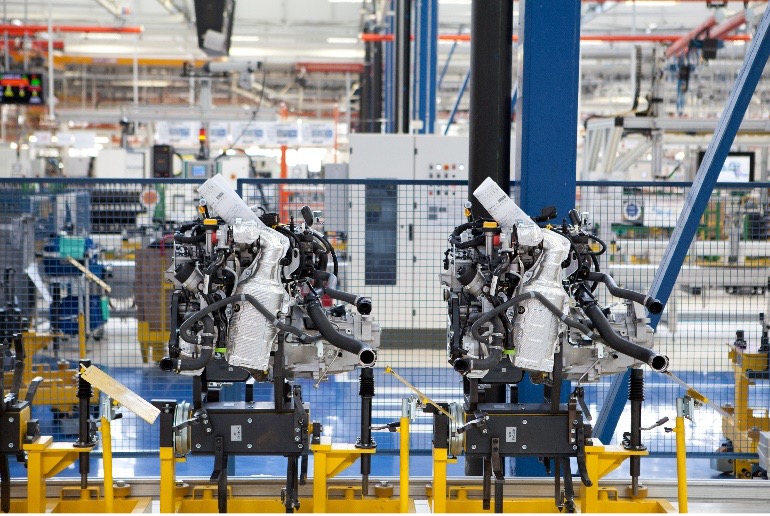

- Assembly Systems

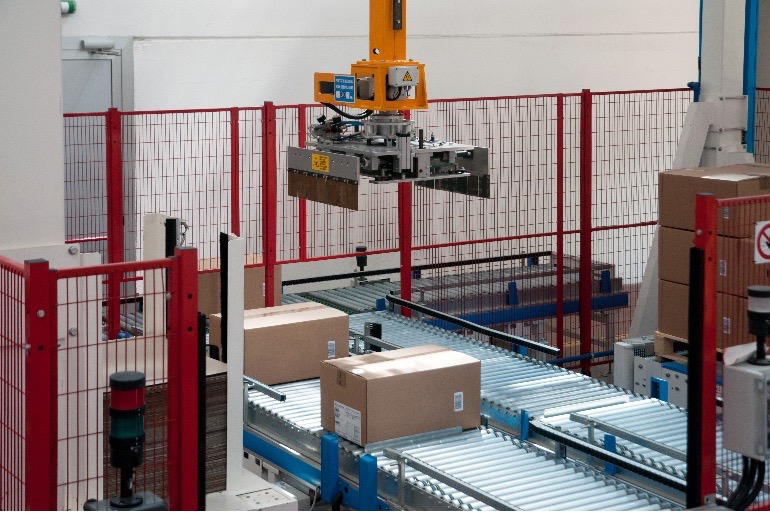

- Packaging Machines

- Quality Control Systems

- Automated Paint or Coating Processes

- Conveyor Systems

- Fabrication Equipment; CNC Machining, Cutting, Grinding.

- Visual Inspection Systems

- Industrial Robots

- Food and Beverage Machines

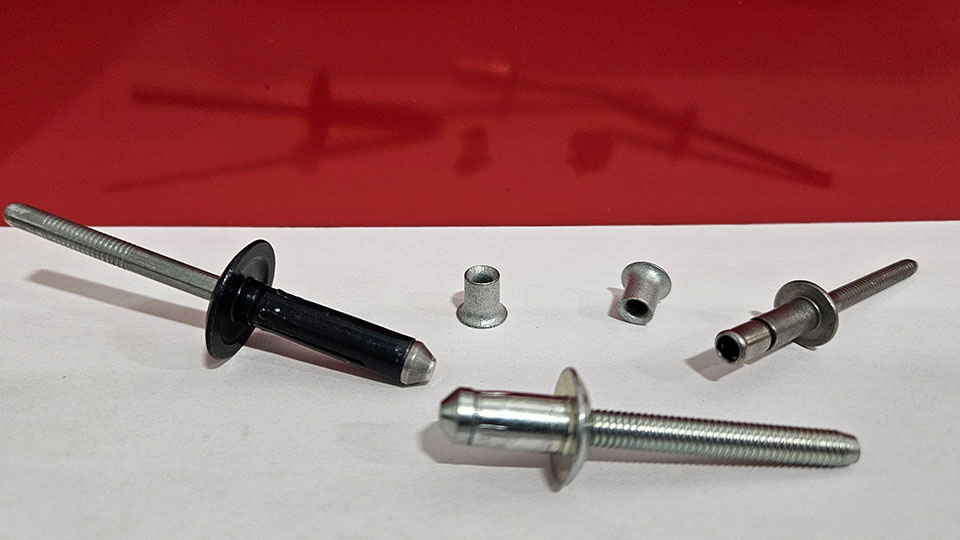

- Automated Swaging Equipment

- Robotic Joining Applications

- Industrial Control Systems

- Data Handling Equipment

- Automated Industrial Transport Machines

Industrial automation replaces human thought with computers and other automated machines. In short, industrial automation is described as a set of technology and automated control devices. It allows for the automatic control and operation of industrial process automation without human intervention. It also achieves superior performance than manual control.

Manufacturing industrial automation components:

Below I list the different types of industrial automation components. Using the hardware with the software is a critical piece of automation equipment that allows the process to become automated.

Industrial Automation Hardware:

- Conveyors

- Industrial Robots

- Sensors

- Fixtures / Tooling

- Carriers or Lifters

- Actuators

- Failure / Fault Alarms

- Collaborative Robots

- Machine Vision Systems

Industrial Automation Software:

- Computers (PCs)

- Manufacturing Execution Systems (MES)

- Programmable Logic Controllers (PLCs)

- Human Machine Interface (HMI) Controllers

- Distributed Control Systems (DCS)

- Supervisory Control and Data Acquisition (SCADA)

- Enterprise Resource Planning (ERP) Systems

- Industrial Networking Systems

- Data Collection / Analytics Tools

Industrial Automation Advantages:

- Higher Quality: Automated work cells are less susceptible to error and more predictable than human operators. Industrial automation provides greater consistency and reproducibility throughout manufacturing, leading to higher-quality products. Automation reduces human involvement and eliminates human error. In addition, automation can maintain uniformity and product quality while ensuring greater consistency. It is possible by adapting control and monitoring industrial processes at all stages, from the conception of a product to its final product.

- Capable Of Larger Throughput: Automated assembly lines can work 24 hours a day and seven days a week, faster and longer than a human operator. Industrial automation allows for flexibility in adjusting the work cell. In addition, the automated system can be programmed offline to make modifications or optimizations for new products with minimal downtime and little to no operator training.

- Robots Are Cheaper Than Humans: After the initial cost of purchasing the industrial robot, only the maintenance and energy costs remain. Robots can also improve the process and increase quality, which results in even more significant cost savings. The cost savings can be extensive over time compared to the salaries and benefits of the company’s workers. Automated machines will reduce the overall labor force and require fewer skilled trades or engineers to maintain the equipment.

- Increased Speed To Market: Industrial automation offers a more efficient production process that reduces product lead time and makes it compelling to keep production in-house over outsourcing. Automated lines can perform change-overs for new products faster and sometimes without stopping production of the current product in the assembly line.

- Improved Operator Safety: Operators no longer have to do dangerous jobs like repetitive tasks, lifting heavy objects under terrible conditions, or working with hazardous chemicals. Robots can perform repetitive and hazardous tasks, making it much safer for all workers in the facility.

- Improve Efficiency: Automating an assembly process increases production efficiency by better controlling the overall system. Automation allows for mass production by dramatically reducing the manufacturing cycle time required for each product and ensuring a higher quality end product is manufactured.

- Reduce Routine Checks: Automation eliminates the need to check process parameters manually. Instead, automation technologies allow the industrial process to automatically adjust process variables to set desired values. It is completed by using closed-loop control techniques with computer vision software. Alarms will sound, and faults will occur if a single station has a parameter out of tolerance.

- Increased Equipment Safety: Automation in industrial manufacturing has increased safety by replacing manual workers with automation equipment that can work in these dangerous conditions. In hazardous places, industrial robots and robot devices are now commonly used.

Industrial Automation Disadvantages:

- Higher Initial Capital Cost: There is a prohibitive initial cost to change from a human to an automated production line. Generally, automation equipment takes about three years to recover the initial investment costs.

- Unskilled Workforce: Training employees to use this sophisticated equipment is also costly, as skilled labor or engineers cost more than unskilled labor. The manufacturing segment in the United States is predicted to have tremendous labor shortages, limiting an organization’s ability to find good talent.

- No Prior Automation Knowledge: When trying to integrate automation on an assembly line, and the staff has no prior experience using this type of automation, this could be very detrimental when getting new technology or automation equipment. If they do not understand the main functions of the automated tools, the line will be worthless and cause plenty of future issues. Read this article and learn why some industrial automation companies fail.

Types of Industrial Automation

Industrial automation can be found in a variety of industries. Automated industrial systems can perform everything, from manufacturing automobiles to food and beverage packaging. Each industrial application has many different levels of complexity.

There are many applications for industrial automation solutions. However, most fall within one of the four main automation types: fixed, programmable, flexible, or integrated. Below are the differences between each type of industrial automation.

- Fixed: This kind of fixed automation can also be called rigid or hard automation. As the name suggests, this type of industrial automation is the least flexible. Fixed automation is used when repetitive tasks and equipment increase productivity and output rates. It is tough to change the process or reconfigure equipment once a fixed automation solution has been installed. Therefore, it is inflexible in offering product variety but offers a lower unit cost. A fixed automation solution can be excellent for high volumes and repetitive operations to increase production. This type of automation uses specialized equipment to automate fixed-sequence assembling and processing.

- Programmable: This automation category is ideal for batch productions where the manufacturing assembly system is subject to change, depending on the manufactured product. Each batch can reprogram its control program according to the sequencing, specifications, and processing responsibilities. Programmable automation allows for the control program to modify specific product changes and assembling or processing operations. The changeover can take time, as equipment needs to be reconfigured from one batch to the next. Programmable automation is most frequently used for medium-sized volumes but can also be used when the costs are acceptable. Therefore, it can be challenging to set up a new product or reconfigure a sequence of operations. This automation system can control all industrial manufacturing equipment.

- Flexible: This kind of flexible automation is known as soft automation. Flexible automation is comparable to programmable automation, allowing for part changes. However, flexible automation can enable product changes to be made quickly and automatically via the control system. It eliminates the need to reconfigure equipment between changeovers. This automation system allows for great flexibility in product design changes. In addition, the changes can be made quickly using the codes provided by the system operators. This automation allows manufacturers to produce numerous products from different ranges in a single industrial process rather than as separate industrial processes or assembly lines.

- Integrated: By unifying devices and machinery under a single control system, integrated automation fosters interconnectedness between operations and production lines, creating a more comprehensive approach to manufacturing. This synergy, amplified by advancements in the Industrial Internet of Things and Industry 4.0, enables individual machines to communicate within a network, enhancing flexibility and facilitating on-demand manufacturing and customization. A key driver of this industrial automation revolution is the introduction of easily integrated monitoring devices. These devices provide real-time data, informing production choices, optimizing supply chains, and managing labor, helping decision-makers identify where and how industrial automation can offer the most substantial benefits.

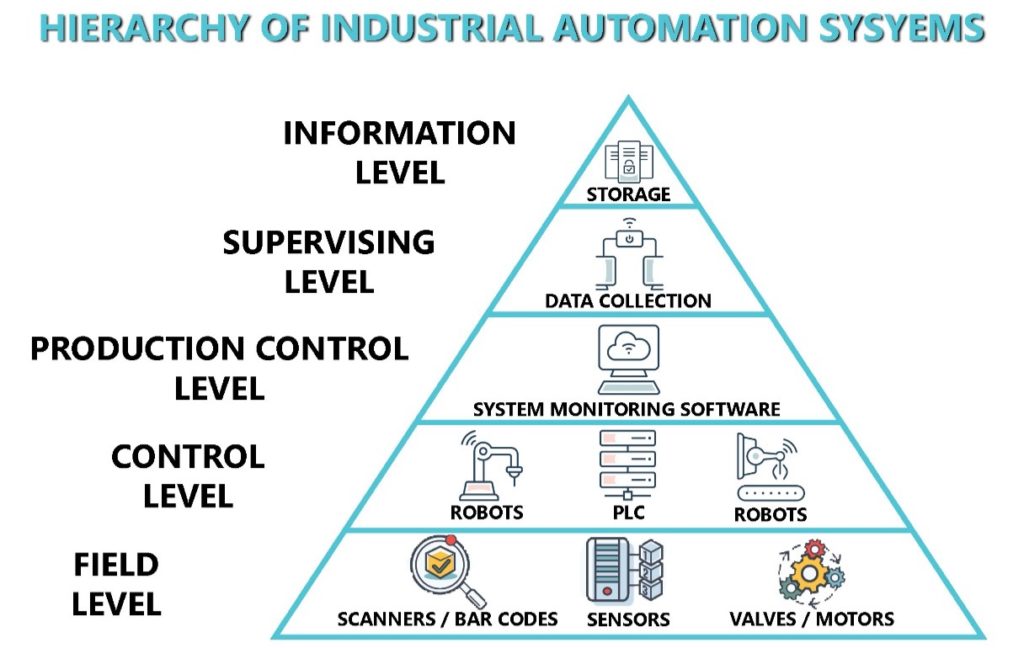

Hierarchy for an industrial automation system.

An industrial automation system may be complex due to the many devices and equipment interlinked with automation technologies. Below is a diagram of the hierarchical levels of an industrial automation system.

The above hierarchy shows that information is continuously communicated from top to bottom. Therefore, this hierarchy can be viewed as a pyramid. As we move up, we get more detailed information about the industrial automated system.

- Field Level: This is the bottom level in the automation hierarchy and includes field devices such as scanners, bar codes, sensors, valves, and motors. These field devices are responsible for transferring data from processes and machines to higher levels of monitoring and analysis. The sensors convert real-time data such as temperature, pressure, flow, and level into electrical signals. The sensors include proximity sensors, thermocouples, and flow meters. It also includes controlling process automation settings through actuators. These are described as the eyes and ears of a specific system. Actuators convert electrical signals from controllers into physical movements by converting energy into force through electrical, pneumatic, or hydraulic means.

- Control Level: The control level can then analyze and monitor the field level data of the automation process. This level includes various automation devices such as CNC machines, programmable logic controllers (PLC), industrial robots, and applications. First, these automation devices acquire process parameters from various sensors. Then, the automatic controllers drive actuators based on the processed sensor signals, the control method, or the program.

- Production Control Level: This level has the most popular robust industrial controllers to deliver automatic process control functions based on sensor input. It includes modules such as a CPU, digital I/O, system monitoring software, and communication modules. It lets the worker program a control process, function, or strategy to perform the industrial automation operation.

- Supervising Level: This is where automatic devices and monitoring systems controllers intervene with the Human Machine Interface (HMI) functions. It will manage different parameters, set production targets, perform historical archiving, and set machine cycle start and stop. The most common equipment used at this level is Supervisory Control & Data Acquisition (SCADA system) or Distributed Control System (DCS).

- Information Level: This is the highest level of industrial automation, and it manages the entire automated system. This level is responsible for production planning, sales orders, and system analysis. Therefore, it deals more with the commercial aspects of the product and less with the technical details. Industrial communication networks are also a vital component in any industrial automation system. They quickly transfer data and communicate from one level to another. These networks are available at all Smart manufacturing automation system levels to ensure continuous data flows through the network. These networks include DeviceNet, Ethernet I/P, Profibus, Profinet, and Foundation Field Bus

What is the future of industrial automation?

Industry 4.0, the Fourth Industrial Revolution, is shaping the future of industrial automation. The combination of physical equipment and digital systems is being increasingly integrated into the industrial process through the advancements of the Internet of Things (IoT), artificial intelligence (AI), industrial robotics, and cloud computing. Industry 4.0 is turning once unintelligent manufacturing into Smart Factories. These Smart Factories are interconnected to machines, have constant communication with one another, and can make decisions independently based on the data they gather. This level of connectivity and digitization results in a highly advanced production system that is both very efficient and highly adaptive.

With the technological advancements of artificial intelligence and machine learning, manufacturing factories are starting also to use this with industrial automation. Machine learning systems can examine large amounts of data, learn from it, and make predictions or decisions without being programmed to perform those tasks. This is very useful in predictive maintenance procedures, where machine learning can predict equipment failures before they happen, reducing downtime and increasing system productivity. Artificial intelligence is helping play a significant role in optimizing system processes, like scrap reduction, energy usage, and the decision-making process.

The Internet of Things, or short “IoT,” is revolutionizing the industrial automation industry by connecting mechanical hardware, software devices, and the people working in these spaces in what was once thought unimaginable ways. This level of communication between workers and machines allows for real-time data collection and analysis, leading to insights that can be used to optimize production lines, increase throughput, reduce complexity, and reduce overall costs. The data gathered from IoT devices can be used to predict faults, establish maintenance schedules, and continually monitor the health of the assembly line. As more and more devices become connected to the internet, the role of the IoT in the industrial automation industry will only continue to grow.

Industrial Automation Conclusion

The industrial automation market has many benefits, such as; increased productivity, improved safety, and high quality at low cost. Many types of automation technology are gaining mass acceptance in various industries. If your business needs help installing or maintaining factory automation equipment, look to an engineering service company like JOINER Services that can help provide contract engineering labor support for any project phase.

Data Resources:

- [1] https://www.nam.org/2-1-million-manufacturing-jobs-could-go-unfilled-by-2030-13743/?stream=workforce