What are automation consulting services?

Automation consulting services revolutionize the way companies look at manufacturing and building products or equipment. Organizations hire temporary industrial automation field experts to help with specific project phases. Automation consulting services can provide professional help for any company using automation for the first time or with years of automation expertise.

Industrial Automation Consulting Services:

Automation consultants can help close the industrial automation gap by putting field experts in your work environment and empowering your organization to reap the benefits of automation. Automation consultants become an extension of your engineering team and allow an organization to create and deploy solutions without providing additional training to new employees.

Automation consulting services can partner with your company’s team and automation consultants to identify high-priority targets and implement solutions using the latest technologies. Identifying key goals helps the automation project by coordinating your team with the business consulting experts to automate workflows and processes that perform their tasks flawlessly every time.

Automate every opportunity in the factory, and expand your business beyond what you thought was possible. The manufacturing industry in America faces major workforce labor shortages, and many companies are now working on employing new automation technology to help complement their understaffed workforce.

Why use automation consulting services?

As manufacturing technology continues advancing almost daily, industrial automation has become an increasingly important part of many manufacturing operations. While implementing automation can streamline processes, increase efficiency, improve safety, increase quality and quality, and reduce waste, it is also a complex undertaking that requires specific expertise to execute effectively. Finding a company that provides quality automation consulting services is critical for the project’s success.

Automation consulting services offer companies the specialized knowledge and experience they need to implement automation solutions effectively with temporary labor support. They can help businesses understand their automation needs, evaluate their existing processes, and identify areas where automation could yield significant benefits. This expert guidance can be invaluable in the development of an automation project.

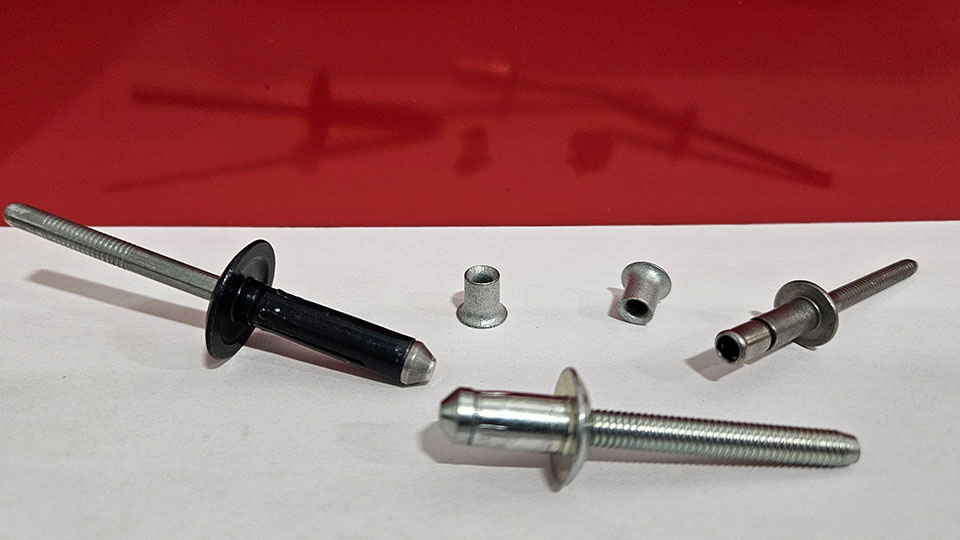

These consultants can assist with the implementation of automation solutions. This often includes programming industrial robots, writing PLC ladder logic, designing new automation process flows, or helping with welding or joining technologies. Automation consultants can also provide training and support to ensure the client’s employees are adequately trained with the new automated technologies.

Automation consultants can also provide ongoing maintenance and production support for any industrial automation equipment. A consultant will help their clients reduce lost downtime and help develop maintenance plans or schedules, ensuring the production line continues to deliver high-quality products.

Consultants in the industrial automation sector also bring a deep understanding of specifications and codes because of their years of experience within the industry. These automation experts can help guide businesses in complying with customer requirements and help them avoid costly mistakes.

Working with an automation consulting services company can have significant savings after a short amount of time. While the investment may seem large initially, the increase in productivity, cycle time reduction, scrap reduction, and overall process improvements can be achieved with the right consultant, and the overall production line benefits can be substantial.

Automation Consulting Benefits:

Automation consultants can provide many benefits to an organization, that include the following listed below.

- They will allow your employees to focus on other tasks while the consultant works on automating the process or equipment.

- The automation consultants will help remove repetitive tasks once done by humans.

- A consultant could provide support during any phase of the project.

- They are not employees but temporary contract help, so the business doesn’t have the added labor cost after completing the project.

- The consultant is responsible for improving productivity at the factory.

- Automation consultants can look at your daily operations to identify the best opportunity to implement an automation solution.

- Consulting engineers can train employees on how to use automated equipment.

Types of Industrial Automation Consultants:

Most automation consultants are experts who must be on-site to help discover new automation possibilities that will empower your employees and improve the business. Automation consultants can help a company with many types of industrial automation, such as:

- Weld Engineering

- Robot Programming

- Controls Engineering

- Electrical Engineering

- Design Engineering

- Program Management

However, some industrial automation companies fail of multiple factors that many do not try to scale correctly across their organization, despite exploring automation efforts through the potential benefit of smaller, more scalable projects. Compared to larger projects with fragmented planning and massive implementation, that often result in lower-than-expected results..

Where to find automation consulting services?

If your business is trying to implement intelligent automation for the first time or looking to improve your current industrial automation performance, the right automation consultants can help the business. Your business must find passionate automation engineers, and working with the right engineering service company is critical to the project’s success.

Working with an engineering service company whose experience spans many engineering functions and industries will be helpful. You want your automation consultant to have seen or solved similar problems in the past, so they can help provide the solution.

Unlike a traditional engineering contract house, they provide anyone from their immediate staff, regardless of whether they are the right consultant for the job. Engineering service platforms can help you find the right individual engineering contractor for your project. They have an insight into the industry’s labor needs and will find the best automation specialist for your problem.

Automation consultants provide support:

Below I list five key areas where an automation consultant can provide support for their clients.

- Engineering Support: Those automation consultants will stay with the project. They will build a relationship with the company staff and try to support the business no matter how often you call them. They understand the infrastructure of automation technology and are a true partner who is up-to-speed on your business and available to help you solve your next task immediately.

- Management Support: Project management is now easier than ever when an automation consultant can focus their expertise on specific targets the client gives. The automation project benefits the clients’ organization by making the workflow and processes easier for the business. Many clients require ongoing automation support services to ensure their project runs smoothly.

- Production Support:A dedicated automation engineer will allow the business to focus on other daily tasks while the new technology is integrated into the current assembly lines. This engineer can be an extension of your staff and are fully committed to optimizing your automation environment.

- Marketing Support: A marketing automation consultant can help the company set up and manage its digital transformation software. They can explain artificial intelligence components and the machine learning aspects of the marketing project while providing the overall automation strategy.

- Training Support: These consultants will help your business and staff succeed. Training allows the consultant, who is familiar with the system inside and out, to train the clients’ staff, so the equipment or system can meet its full potential. These experts can evaluate your operation and identify opportunities to empower your employees and drive the business forward.

Why your business needs industrial automation?

Businesses create standard processes to ensure that their employees do not forget the necessary steps or to keep them organized if they have to do a repetitive task. These business processes make sure that all business operations are consistent and compliant. Business processes need to be consistent across multiple executions.

The reason companies need industrial automation investment is so they can diminish errors and increase productivity while eliminating the need for manual processing. Industrial automation will contribute to the overall success of the business. Automating business processes can also improve compliance, which can help organizations avoid violating laws and regulations that could lead to heavy fines.

Automating business processes also helps prevent costly errors that can significantly impact the company’s bottom line. Companies that automate core and support basic functionalities can speed up business operations, which allows for more efficient work and less repetition.

Automate manufacturing processes!

Industrial automation is becoming more popular in manufacturing organizations. This indicates that there is a growing demand for operational efficiency. Automation consulting services help business owners understand the automation journey and which processes must be automated first to see immediate results.

For example, your automated business processes, such as placing boxes on a pallet from an assembly line, must be done at a specific time or when certain conditions on the line are set. Instead of relying on employees to remember each step, automating repetitive processes can make it easier, safer, and less risky for organizations. These workflows can be great tools that trigger events or run at specific times.

Automate your production lines.

Many repetitive assembly processes can now be automated with industrial robotics, joining technologies, or control systems. Automating these processes can improve operational efficiency.

You’ll be able to reduce the amount of manual labor involved. Automated production lines will allow you to use fewer resources for expansion. Automation can speed up the work process by requiring fewer repetitions or tasks.

Automation can also reduce errors and operation costs after the initial capital investment. Automation will reduce manual data input and still produce the same quality output as computer-controlled programs. It automates business processes, allowing customers to concentrate on the customer and not repetitive tasks.

Automate software and hardware to make the business successful.

It is essential first to understand the company’s needs and then reach out to automation experts who offer automation engineering services. It is vital to communicate your priorities, business processes, project scope, and workflows so they can propose a plan to implement the robotic process automation and achieve your targets.

Automation promises to improve efficiency with various software programs and hardware applications. Using automation systems to increase organizational efficiency and throughput goes beyond the software or hardware packages. An automated system should do the following: process modeling, workflow design and integration, access control, security and data analytics management, and communication. These factors are essential to achieving operational excellence when automating your processes or equipment.

Automation consulting services can increase the business’ profitability!

Engaging with skilled engineering professionals in technical areas is vital to unlocking the potential of business process automation. Automation consultants will allow the company to benefit from their expertise in automating complex environments. In addition, automation consulting experts that use the JOINER Services engineering service platform can help you develop strategies to optimize your teams and implement workflow automation that results in fewer errors and greater profitability.