Engineering service companies provide consulting or contracting services that help clients market their products or technologies. The level of specialization of the engineering disciplines of the client will determine the project scope. Each engineering firm will provide different engineering solutions and engineering capabilities, so it is up to the client to determine the required specifications for each project.

What does an engineering service company do?

The basic functionality of any engineering services company is to provide an engineering expert who can help their clients resolve issues. Lots of organizations only need temporary consultation. That is why having an engineering services partner who can provide the team with excellent engineering staffing resources is critical. Many of the engineers from these engineering firms can help with emerging technologies in innovation because of their past consulting projects.

An engineer’s work scope will depend on their engineering profession. For example, a program manager would not usually be qualified to authorize electrical engineering, and a product design engineer would not do weld engineering tasks. Most professional engineers are only trained in one profession. This means they can only perform tasks within their specific area of expertise.

A reputable automation engineering services company will have experts in many engineering disciplines. This allows clients to have smaller, more focused internal engineering teams and contract out a project or the product development process to an engineering services company.

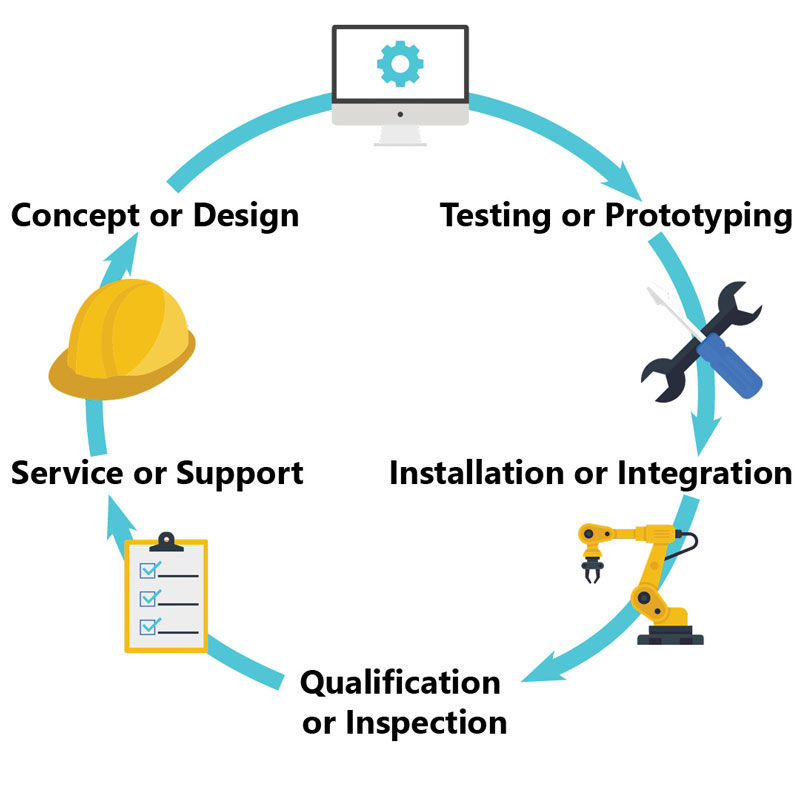

5 Phases of Engineering Services:

Many engineering services companies can provide multiple phases of consulting from; concept, prototyping, installation, qualification, and support of projects. Below are the five types of services provided by most engineering service companies.

- Concept or Design: This phase, also known as the pre-project phase, is when ideas are collected, and the project drawing of sketches, prints, layouts, or schematics is initially created. Project scope planning, such as; timelines, team size requirements, budgets, and goals, are set during this phase. Project risks are also calculated during this phase of the project.

- Testing or Prototyping: The product or system will be examined during this phase. The team will thoroughly analyze the product or system for defects that must be fixed before implementation. In addition, testing and simulation of the parts must meet the quality compliance standards the client or customer specifications set.

- Installation or Integration: After passing initial product testing, installation or integration of the product or system is then performed. At this time, the infrastructure is built to manufacture the product. The system or product will now be integrated and installed at the customers’ facility.

- Qualification or Inspection: As the product starts to be manufactured, quality assurance checks will verify customer specifications and product quality. At this time, they will troubleshoot any faults or issues that arise during these verification checks.

- Service or Support: After deployment, workers will move into a support role to maintain the services provided to the product or system. They will be responsible for any changes that need to be performed to ensure quality and performance.

Specialized Engineering Services:

Many companies that offer engineering services can provide extensive consulting to companies needing guidance and help their clients find engineering solutions to their problems. In addition, most specialize in niche areas of engineering to differentiate themselves from their competition.

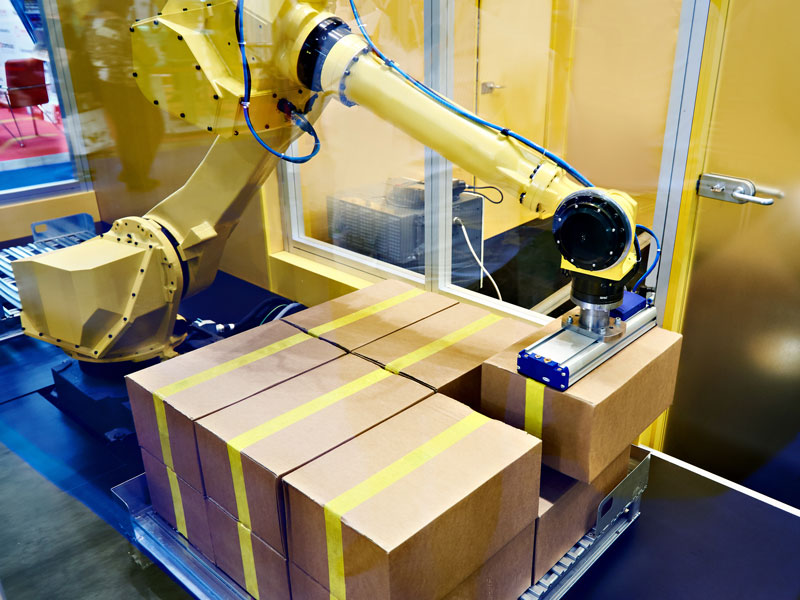

Engineering services in industrial automation are often combined with manufacturing. As a result, many automation projects require specialized skilled professionals.

An engineering company is responsible for providing the right engineering staff that meets the client’s needs for the project. For a project to be labeled a “success,” the client must give details of each consulting engineer’s responsibilities and tasks. This information must be written as a measurable goal during the initial start of any consulting project.

Ensuring the consultant knows the clients’ relevant codes or the industry standard is one of an engineering service company’s most essential services. Each consultant must have some prior knowledge of the services, equipment, or process they will work on with the client.

Engineering services companies and engineering contract firms work with many organizations across many industries. This gives the company’s workers a broader, more knowledgeable workforce with various industry experiences.

What services are offered by engineering service companies?

The services offered by engineering automation companies differ depending on their size, structure, capabilities, and type of work.

Before entering into any contractual agreement with an organization, verifying that the engineering services company’s workers can meet your project needs is essential. This is usually done by vetting an organization via prior client references or meeting with individual contractor who will be working on your project.

Many contract automation engineering companies offer a wide range of engineering consulting and manage subcontractors or business affiliates while taking on the full responsibility of the contractors for the entire project. This allows companies to focus on defined areas of engineering, such as welding or joining, controls engineering, and robot programming.

6 types of industrial automation engineering services.

There are many types of engineers in more specialized industries like industrial automation. Here are six of the most in-demand and common types of engineers in the automation field.

- Controls Engineers: Contract controls engineers are skilled in programming programmable logic control (PLC). These automation systems engineering professionals use a control system to communicate between machines and equipment. They are the brains that tell the equipment how and when to function.

- Design Engineers: They are responsible for the design process of a product or system. A design engineer must build ideas into reality. They also verify that the mechanical engineering components on the project can be manufactured to specification.

- Electrical Engineers: An electrical engineer will assist with electrical components, control systems, or equipment. They are responsible for anything with electrical power consumption during the automated process. They can also help with the design of electrical schematics.

- Program Managers: A program manager will oversee the entire project management or parts of the program. They implement the strategies, delegate, and are responsible for getting the team to meet client targets. As a contractor, the goal of a program manager is to improve the client’s performance while staying on time and within budget.

- Robot Programmers: These automation experts can program industrial robots to perform required manufacturing tasks. One of their main goals is to meet cycle time demands set by the client. In addition, they can help clients program different robot application types, from material handling, welding, or dispensing applications.

- Weld Engineers: A contract weld engineer can help with any significant or minor welding application. They will know multiple automated welding processes. These engineers can also help with welding codes and client specifications.

Who can be an engineer for an engineering services company?

These engineers must have the proper education, training, or experience in their specialized automation engineering field. They could be right out of school or in the industry for 30 years. Some engineers jump into contract work because of the opportunity of working on many projects and obtaining vast amounts of industry knowledge so quickly.

Contract engineers may also manage complex products, equipment, and systems engineering. They will ensure that work is feasible and compliant with established codes and standards. These engineers are responsible, independent, and can handle high-stress situations during a project’s lifecycle.

Who needs engineering service companies?

Engineering service companies cater to a wide range of clients and industries. Many manufacturing and industrial companies use engineering service companies to help design, develop, and optimize their current products or processes. They also help them with the quality and support of those products or manufacturing processes.

Construction companies collaborate with engineering service companies to ensure their designs meet structural, electrical, plumbing, and other engineering requirements. Engineering services provide the technical expertise to translate design concepts and building prints into feasible and safe structures. Engineering service companies are crucial in large-scale infrastructure projects such as roads, bridges, tunnels, airports, ports, and utilities. They provide expertise in designing, planning, and implementing these projects, ensuring safety, efficiency, and sustainability.

Research and development companies that work with new technologies or innovative solutions often require engineering services to support their product development efforts. This may involve prototyping, testing, and optimizing new technologies, components, or systems.

Engineering service companies can also provide valuable support to small businesses with innovative ideas but who lack in-house engineering capabilities. An engineering service company can help a small business scale and grow without having the additional overhead cost once the project is completed.

Why use an engineering service company?

Below I list and describe why companies should work with engineering service companies.

- Field Experts: Engineering service companies possess specialized knowledge and expertise in various engineering disciplines. They have skilled professionals with extensive experience in their respective fields, enabling them to provide technical solutions and insights that may be beyond the capabilities of in-house teams.

- Cost Efficiency: Hiring an engineering service company can be cost-effective compared to maintaining a dedicated engineering department within a company. It eliminates the need for continuous investment in infrastructure, equipment, training, and overhead costs associated with hiring and retaining specialized engineers.

- Scalability: Engineering service companies offer flexibility regarding project durations and scope. Companies can hire them on a project-by-project basis, allowing for scalability based on the specific needs and requirements at any given time. This flexibility enables companies to focus on their core competencies while leveraging external expertise when necessary.

- Access To Technology: Engineering service companies stay current with the latest tools, technologies, and software applications relevant to their field. By partnering with them, companies gain access to these resources, enabling them to benefit from advanced modeling, simulation, and analysis tools that may be expensive to acquire and maintain in-house.

- Reducing Risk: Engineering service companies help mitigate risks associated with complex projects. They bring experience and knowledge from working on similar projects, allowing them to identify and address potential challenges and risks proactively. This helps reduce project delays, minimize errors, and ensure compliance with project or other customer requirements.

- Efficiency: Hiring engineering service companies that can leverage their specialized staff and company resources to complete projects more efficiently and within specific timelines. The service provider’s experience and streamlined processes can accelerate project completion, reducing time-to-market for new products and meeting project requirements.

- New Ideas: Engineering service companies often work with diverse clients across various industries. This exposure allows them to bring their clients new ideas, creative concepts, and best practices used in different sectors. This can lead to innovative solutions, improved efficiency, and more straightforward manufacturing methods.

- Focus On Competencies: Outsourcing engineering services allows companies to focus on their core business activities. By delegating specific engineering tasks to experts, companies can redirect their internal resources and attention toward strategic initiatives, product development, customer service, and other areas critical to their core competencies or standard business operations.

Is using an engineering service company expensive?

The cost of engaging engineering service companies can vary depending on various factors, including the scope and complexity of the project, the level of expertise required, the duration of the project, and the specific types of services being provided. While engineering service companies have associated costs, it’s essential to consider the value they bring and the potential cost savings they can provide in the long term.

It’s advisable to evaluate the specific needs of your company or project, obtain multiple quotes from different service providers, and consider the expertise and track record of the engineering service companies before making a decision. This will help ensure you receive the best value for your investment.

If your company is looking for engineering services in the industrial manufacturing or automation industry, try JOINER Services. Their network has talented engineers who can help with most engineering projects. Learn more by visiting their engineering service page.

Find the right engineering service company!

An excellent engineering services company doesn’t just take on a project to tell a client what or how to do their project. Instead, the goal is to find an engineering company whose staff can easily collaborate with the client’s engineering team.

Ensure the company asks the right questions before hiring any engineering service company. If you want to find the best engineering contractor, vet each candidate properly before hiring any contractor. Finding a consulting engineering firm that is affiliated with the American Council of Engineering Companies of Michigan is also a great way to know if the company will be able to meet every discipline of engineering that your business needs. The business must take the correct steps to ensure the contract will fit the project’s needs. Otherwise, it is a gigantic waste of time and money.

Communication between the engineering service company and the client is also essential. For example, the client should provide the engineering service company with weekly progress updates on each contractor throughout the project.

An excellent engineering service company knows its clients and will do as much as possible to support them throughout each project phase. This means ensuring that the client’s profitability goals and project tasks are met, even if not beneficial to the engineering service company.