In this article, you will learn about industrial automation contracting. In today’s world, the key to have better efficiency and product quality lies in automation. And that goes for almost any industry out there, but especially for manufacturing.

However, it’s the industrial automation engineers who plan, implement, and manage these advanced technologies in a company’s production lines. If you’re thinking of hiring an automation contractor, here’s what you need to know about what they do, the benefits they offer, and where to find the best ones.

Industrial Automation Contracting:

An industrial automation contractor will be hired by a company temporarily in the industrial automation fields for help on specific project phases. These automation consultants provide specific help for their clients who use automation.

What do industrial automation engineers do?

Industrial automation engineers are the go-to experts for making manufacturing processes more efficient and smooth-flowing. Basically, their main job is to design, build, and support automation systems that fit their client’s specific needs.

These professionals kick things off by assessing what the facility needs to up its game and then figure out the best tech solutions to get there. Aside from planning, they also get hands-on by programming and setting up the systems to make sure everything runs smoothly.

Their skills and expertise are needed to make sure these complex automation solutions do their job right and help keep the production line humming along efficiently.

What is an industrial automation contractor?

Industrial automation contractors work with their client’s engineering teams, offering technical services and professional advice. The role of an industrial automation contractor can vary from highly specific technical assistance, like controls engineering services or robot programming services, to project management services. Collaboration with the contractor and client team members is expected while coordinating each specific project task. They may also be asked to provide technical insights into different areas of the automation process.

What is industrial automation?

To learn about industrial automation contracting, you must first know some of the basics of industrial automation. Industrial automation uses hardware equipment and computer software to manage industrial machines to reduce labor, increase quality, decrease manufacturing cycle times, and increase productivity. These software and hardware packages include process control systems, industrial robots, programmable logic controls (PLCs), human machine interfaces (HMIs), industrial robots, motion control, actuators, motor controls, and sensors. The automation system’s data is collected and then stored as real-time information that is used for machine learning, tracking productivity, downtime, fault logs, and cycle time calculations.

One of the main reasons some companies fail with industrial automation is that they are not skilled in system integration and do not properly staff the right industrial automation contractors. JOINER Services is focused on making sure companies hire the right talent for their project by using individual contractors selected based on specific automation project needs.

How to find an industrial automation contractor?

Below, I list the top ways to find industrial automation contractors.

- Search Nationally: Expand your search criteria to find the best individual for the project because it could be someone not located near the work area. Industrial automation contractors can be found throughout the United States, so do not limit the company to local talent. This approach sometimes comes with added costs, but when the contractor does a spectacular job for their client, the cost is rarely an issue.

- Job Fairs / Networking Events: Networking with personal and professional connections is a great way to find contractors. This is often a great way to get references or referrals from work colleagues or business acquaintances. You can find great automation companies and people at many fairs, trade shows, or networking events, such as Manufacturing in America, The Pack Expo, and Automate. Attending these networking events is a great way to make lifelong professional business partners and future co-workers.

- Engineering Service Platforms: Websites like Upwork and JOINER Services connect businesses with independent contract engineers. These engineering service platforms make it easy for companies to access hundreds of contractors to help them find workers quickly. These platforms are simple to use and are in the industrial automation industry, so you will likely find an excellent, skilled individual for any project.

- University Recruitment Services: If a company is looking for degreed younger talent out of college, then check out the university recruitment services provided by College Recruiter, College Central, or Handshake. A company can use these recruiting services to help college students find employment after graduation.

- Online Job Boards: Post the contract job opportunity on one of the many job board websites such as LinkedIn or Indeed. This will allow you to target a specific audience to get more applicants applying for your open contract job. Some of these resources are free for companies for a limited number of days or depending on applicants or the number of jobs posted.

- Consulting Firms. Many automation consulting firms provide these types of engineering services to their clients. Usually, a quick search online using specific key terms like contract robot programmer or contract controls engineer can be done to find an industrial automation contract company.

Are you looking for more great tips on finding engineering contractors? JOINER Services makes it easy to find controls engineering services or robot programming services.

The benefits of outsourcing industrial automation engineering services.

Hiring an in-house engineer or team to plan, implement, and manage your automation technology is not always doable because of all the time, money, and effort it takes. So, what’s the next best solution?

Outsourcing!

Engineering contractors are experts who provide their skills on a project basis. Here are several reasons why outsourcing might be the best move for you:

It May Be Less Expensive:

It’s no secret that outsourcing is one of the best ways to save money and keep your cash flow in the green. You can save on the significant costs that come with keeping a full-time automation team, like salaries, health benefits, and ongoing training. This way, you only shell out cash when you actually need the work done, which can help keep the budget in check.

You Get Access to Expertise:

When you outsource, you tap into an automation pool of specialists who live and breathe automation. These professionals bring deep knowledge and experience with the latest tech to the table and often deliver more sophisticated and innovative solutions than what might be managed in-house. Plus, you have the freedom to choose a professional who has experience in a specific task you need to do, from project management and implementation to business management and consulting services.

You Can Scale as Needed:

Need more hands-on deck during a production spike? Or maybe less when things slow down? Outsourcing your contractors gives you the flexibility to scale your automation efforts without the hassle of hiring or firing. This is a big plus for industries where production needs can change in the blink of an eye.

A Better Focus on Core Business:

Letting the experts handle automation means that your main team can stick to what they do best, whether that’s developing new products, marketing them, or winning customer loyalty. This can lead to better work performance, as each part of the business gets the attention it deserves.

Risk Management:

Diving into new technologies or ramping up production can come with risks. Outsourcing places much of this burden on the shoulders of the external partner, especially when it comes to navigating compliance and ensuring technical reliability.

Speed to Market:

External automation teams often work faster than in-house crews, mainly because they’re not pulled into other internal issues and projects. In turn, increased efficiency can speed up production and help companies get their products out faster, which provides a valuable edge over competitors.

Things to consider when hiring industrial automation experts.

Looking to hire industrial automation experts? Here are several important factors to keep in mind to make sure you choose the right fit for your industrial automation company:

Experience and Track Record:

Take a good look at your candidates’ past projects. It’s important to check whether they have experience with businesses similar to yours and if they’ve consistently delivered good results. Positive testimonials and case studies can be a great indicator of their capabilities.

Technical Expertise:

Make sure they’re up-to-date with the latest technologies in the automation field. Ask about their familiarity with the systems and processes that are critical to your industry to make sure they can handle the specific challenges your company faces.

Cultural Fit:

You want an automation expert that meshes well with your team. They should be able to collaborate effectively with your employees and align with your company’s values and work ethic. This can make a big difference in how smoothly projects run.

Support and Maintenance:

Find out about their follow-up support. Effective post-implementation support is non-negotiable, as you’ll want to see to it that your new systems are maintained properly and any issues are quickly addressed.

Cost:

While it shouldn’t be the only factor, cost is always a consideration. Make sure their fees align with your budget, but also consider what you’re getting for that price. In some cases, paying a bit more upfront on contractors can save you money in the long run by avoiding downtime or frequent repairs.

Project Management Skills:

Check how they manage projects. Efficient project management means they can deliver on time and within budget, which keeps your operations from facing unnecessary disruptions.

How much do industrial automation contractors cost?

Industrial automation contractors’ costs usually vary depending on many different things. Below, I list the common factors that go into the cost of an industrial automation contractor.

- The first thing you might notice is the cost difference between working with an independent engineering contractor compared to working with an engineering firm.

- If the service is done on-site or remotely, this may affect the contractor’s cost.

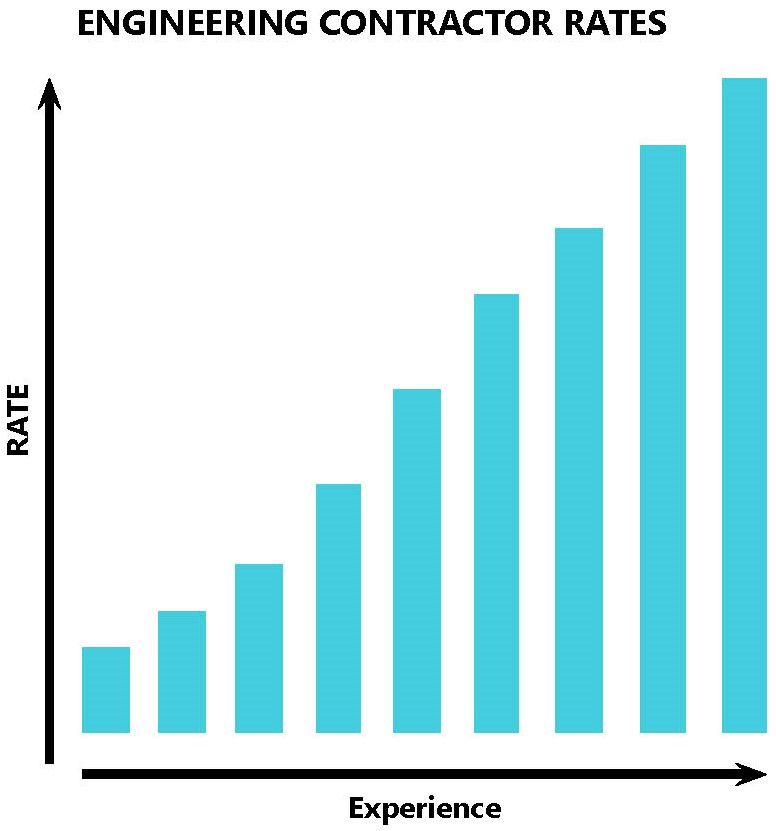

- The years of experience a contractor has will also affect in cost.

- The type of engineering service that is required.

It is hard to give specific rates for a job without background details, but generally a good rule is the more qualified the contractor, the higher the hourly rate, as shown below.

Looking for an industrial automation contractor? Contact us now to get pricing quotes for your project.

Industrial Automation Contractor Salary:

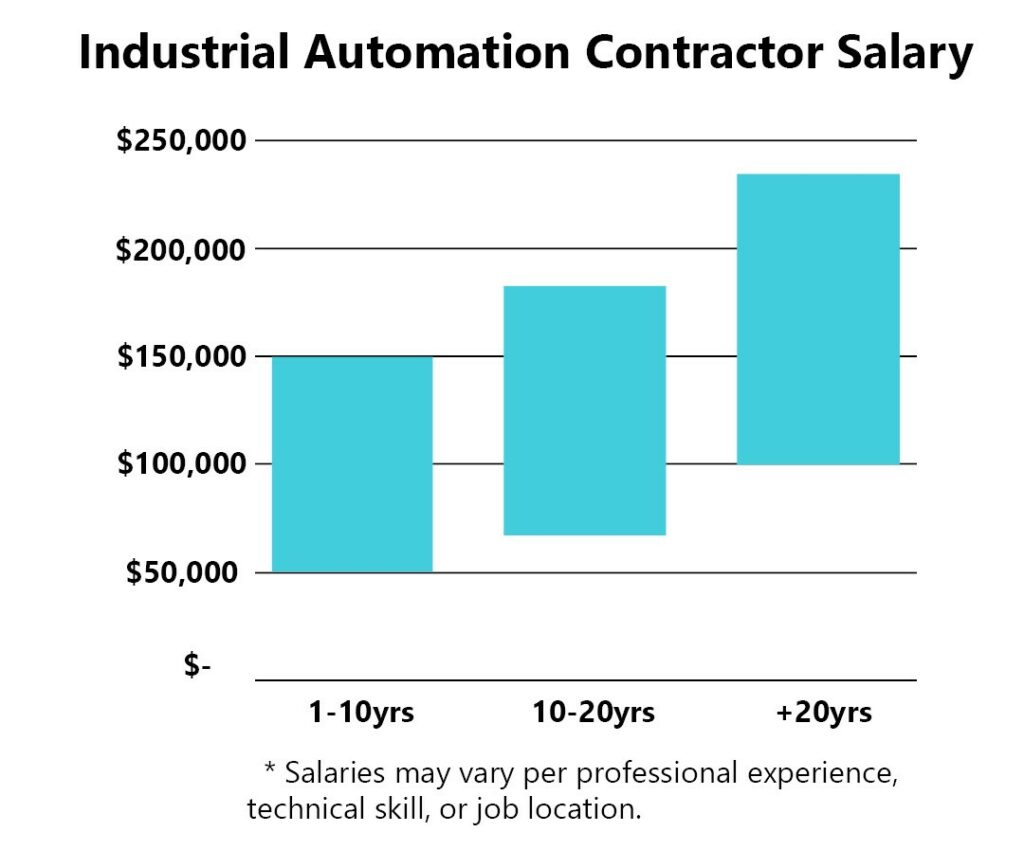

The salary of an industrial automation contractor can vary depending on several factors that include work location, years of experience, technical skill set, and the person’s type of work status (W2 or 1099). It is good to note that the figures I list below are approximate numbers we see at JOINER Services, and this may not reflect your specific industry salary:

It is also important to note that performance incentives, bonuses, or other forms of payment can also supplement salaries in the industrial automation field. More senior consultants who work with many different clients can earn more depending on their professional engineering services. It is important to research the salary ranges that are specific to your job in correlation with degree, industry, and location. It is always a wise practice to know the job market values to better understand current salary rates.

Industrial Automation Contractor Jobs:

Depending on a person’s technical skills, being an industrial automation contractor can be a highly sought-after career. Jobs are available in many industries like food and beverage, industrial manufacturing, pharmaceutical, tool and die, automotive, and many other industrial industries that use automation equipment.

Automation consultants are available for all types of automation industries. A consultant may work for an engineering consulting firm, an engineering services company, or as an independent contractor who outsources their own automation services to clients. Who you work for depends on each contractor’s personal preference.

There are many new alternative options for automation engineers to find work compared to working for traditional engineering service companies, like JOINER Services, which offers independent engineering contractors the opportunity to find new clients using their platform. Remote work as an automation contractor is also becoming more common as companies can do simulation work and remote into automation technology as long as the system is connected to the internet.

Industrial Automation Contractor Training:

There are many different types of industrial robotics or automation courses available for onsite or classroom training. Clients often use an automation contractor to help train their employees. By hiring an outside resource to help train their employees for several weeks or months can lead to an increase in automation skills within the company’s workforce and increase their production efficiency.

A company may be growing rapidly, so industrial automation training will need to keep pace with the growth of the business. Training company employees is essential, and more cost-effective than having to hire new skilled employees. Receiving relevant and quality training can be done by an experienced industrial automation contractor.

Many industrial automation contractors have experience in training client’s employees after a project is completed. Industrial automation training classes could last one week or several months. The training will help automation engineers and automation technicians because the contractor can teach the team members how to operate the automation equipment, systems, processes, or industrial robots.

Types of Industrial Automation:

Industrial automation is found in a variety of industries, and each industrial application has many different unique complexities and challenges. There are many applications to use industrial automation solutions, but most solutions fall within one of the four main automation types: fixed, programmable, flexible, or integrated. Below, I list the differences between each type of industrial automation.

- Fixed Automation: Fixed automation can is also known as rigid or hard automation. Fixed automation uses specialized equipment in fixed-sequence assembling and processing. This process makes it difficult to perform part changeovers and is used when tasks are highly repetitive and with high volumes of parts.

- Programmable Automation: Programmable automation is perfect for batch production when the manufacturing assembly system is subject to changes in the manufactured product. Each batched product can reprogram its controlled program according to the specific sequencing specifications and processing tasks. Programmable automation is best for medium-sized production volumes. It is not easy to set up or change product lines.

- Flexible Automation: Flexible automation can enable product changes, similar to programmable automation, but the changeover can be made quickly and automatically with a control system. This kind of automation removes any need to reconfigure equipment between product changeovers, which allows for greater product flexibility. System operators can perform these changes quickly, allowing manufacturers to produce numerous products with a single assembly line.

- Integrated Automation: Integrated automation is a more comprehensive approach to manufacturing because of the interconnectedness between operations and production lines. This collaboration enables individual machines and automation systems to communicate within a network that allows for the greatest flexibility and customization in manufacturing. Integrated monitoring devices provide real-time feedback and data collection that optimize supply chains.

Industrial Automation Solutions:

Below, I provide a common list of industrial automation solutions often used in automated systems.

- Industrial Robots

- Programmable Logic Controllers (PLCs)

- Conveyor Systems

- Vision Inspection Systems

- Scanners

- Quality Control Systems

- Data Storage Software

- Servo Motors

- Part Present Sensors

- Hydraulics

- Pneumatics

Why use industrial automation contractors?

When deciding if your company needs contract support, it is critical to contemplate the positive and negative associations with using outside consulting resources. The reasons I list below should help you make an informed choice about working as an industrial automation contractor.

The benefits of using industrial automation contractors:

- A contractor will allow current employees to focus more on their own tasks while the consultant works on the industrial automation equipment or processes.

- They will be willing to work long hours and on weekends.

- Most likely, the automation consultants will already have experience working on similar automation equipment

- An automation contractor can provide support for any phase of the project.

- A contractor is not an employee but temporary help, so the company will not have the added labor cost once the project is completed.

- The automation contractor is responsible for improving inefficient production lines.

- A consultant can view the daily operations and procedures to identify opportunities to implement automation solutions.

- A contract engineer can train employees on new or existing industrial automation systems or equipment.

- They can help with developing machine safety procedures and machinery documentation.

Top 5 Industrial Automation Platforms for Outsourcing Contractors:

When considering outsourcing industrial automation, you’ll want to partner with a company with a strong reputation for quality, reliability, and innovative solutions. Here’s a list of some top companies that specialize in industrial automation services and outsourcing:

JOINER Services

Need someone to address your manufacturing automation needs quickly? JOINER has hundreds of professionals across dozens of engineering fields, all in one platform. From welding automation to advanced engineering techniques, JOINER’s engineers can provide exactly what you need.

The process is simple: join for free, create your business profile, and start browsing engineer profiles to find the right person for the job.

Field Engineer

Has contract jobs in over 200 countries and thousands of vetted engineers on its platform. They will algorithmically match the most qualified engineers for each job. The engineers who opt-in to their platform have completed a background checked and are ready to work. You are able to filter and sort contractors by rating, their years of experience, and how close they are to your facility.

PE For Hire

On its platform, licensed professional engineers (PE) provide their training, education, and professional expertise to analyze and solve client’s engineering problems in the areas of research, design, manufacturing, and construction. If you need to find a licensed professional engineer for hire? Use their platform to get free professional engineering quotes from a nationwide network of licensed PE consultants and professional engineering companies.

Rule 5 Hire

Its automation division assists companies by providing top automation professionals from around the country. Their engineers provide automation solutions nationwide while working with clients from one client to the next. They ensure costs stay within their clients’ budgets. From robotic engineers to PLC programmers, controls engineers, automation technicians, and preventative maintenance professionals, they have many contracting options for their clients.

Turing

Turing combines its internal experts with global talent while using proprietary AI technology to support companies and careers more efficiently. Its vetted and sourced technical professionals from around the world match client projects with its engineers.

Where to find industrial automation contracting services?

If your company is looking for industrial automation consulting services, then you must find talented automation contractors and work with the right engineering service company to ensure the success of the project. Working with a company whose experience extends into many automation engineering functions and industries is helpful. You want your automation contractors to have used or seen equipment and issues in the past so they can help provide you with a solution.

FAQs About Industrial Automation

Below, I describe some frequently asked questions about industrial automation.