What does a contract joining engineer do?

Contract joining engineers are responsible for their client’s joining processes. They ensure projects meet client specifications, mechanical joining codes, and joining process requirements. A contract joining engineer brings their prior experiences to a project. They have seen many joining applications and processes and worked in various industries.

Contract joining engineering services typically provide on-site engineering support at the client location. They can assist with on-site mechanical joining training courses. These companies can better understand their joining process by working with a contract joining engineer to ensure their joining projects are completed correctly, safely, and efficiently.

A contract joining engineering provides companies with worker flexibility. Companies can use a contract employee for specific projects instead of hiring a full-time employee. This allows companies to bring in these specialized mechanical joining experts as needed without having the costs of a full-time employee.

Contract Joining Engineer Job Description:

These tasks are often found in the job description for joining engineers:

- Provide a joining equipment list to identify consumable costs.

- Read and understand mechanical joining requirements.

- Understand cycle time constraints and meet production cycle time targets.

- Maintain mechanical joining quality standards throughout the process.

- Identify joining inspection methods.

- Program industrial robot paths.

- Create mechanical joining procedures and maintain all technical documentation.

- Identify the best type of joining process for the application.

- Validate mechanical joining quality with destructive and nondestructive testing methods.

- Train technicians and engineers with the joining equipment and technologies.

- Understand the spare parts and consumables list for each joining process.

- Successfully set up the mechanical joining processes and the equipment during the installation or integration.

- Support all mechanical joining applications and processes during production.

How to find contract joining engineers?

It can be difficult to find contract joining engineers if someone does not know a company that provides those contractors. One can quickly look at an engineering service platform like JOINER Services to find talented mechanical joining engineering services. They can find the right individual with the proper joining background, which is critical for project success.

Clients often want to see more than the contractor’s resume when looking for a joining engineer. They often want to see the contractor’s professional references from previous contract engineering jobs and view a rating system to help them select the right contractor. With engineering service platforms like JOINER Services, these clients can now use an unbiased resource of talented contract engineers to find the right contractor for their specific project.

With qualified employees, a well-reviewed plan, and a strong management team, the right joining engineer can ensure any project is successful.

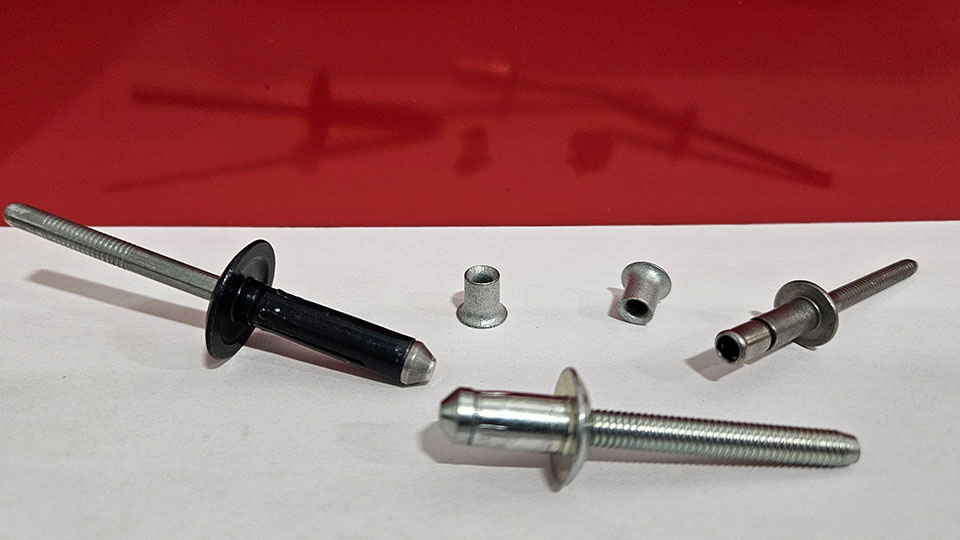

Different types of joining processes:

Below, I list the most common types of joining processes used in the manufacturing industry.

Mechanical Joining Processes:

- Mechanical Clinching

- Clinch Riveting

- Self Piercing Riveting (SPR)

- Flow Drill Screws (FDS)

- Blind Riveting

- Punch Riveting

- Fasteners

- Riveting

- Bolting

Chemical Joining Processes:

- Gluing Applications

- Sealing Applications

- Adhesive Bonding Applications

Metallurgical Joining or Welding Processes:

- Resistance Welding

- Arc Welding

- Laser Welding

How to become a joining engineer?

If you want to become a joining engineer, then your education is one of the first things to consider. Many colleges and universities across America offer different types of degrees that could lead to a career in joining engineering. I list different degrees below to consider when looking for a choice.

- Engineering Technology, Materials Joining Concentration

- Mechanical Engineering Technology

- Mechanical Engineering

- Mechanical Joining

- Weld Engineering

- Materials Engineering

- Metallurgical Engineering

- Advanced Joining

- Industrial Engineering

Working as a joining engineering contractor directly after graduating from college or university is a great way to build industry experience in the manufacturing and automation industries. These recent graduates find that they can travel to new client factories monthly, if not weekly, and quickly gain a vast amount of experience with these joining processes, setting an excellent foundation for the start of their careers.

If you want to become a joining technician without a degree, know this is possible through years of experience working with one or multiple types of joining processes. Technicians can be just as valuable, and in some cases more valuable than degreed engineers. If you are constantly willing to learn about joining technologies, you can become a professional in the joining industry.

Contract Joining Engineer Responsibilities:

These responsibilities are often required of contract joining engineers:

- Repair different joining equipment and replace their consumable parts.

- Ensure that equipment safety protocol is in place.

- Program the joining parameters.

- Understanding of chemical and material behaviors during the joining process.

- Troubleshoot or debug joining processes and equipment.

- Identify when semi-automatic or fully automated systems should be used.

- Comply with all joining specifications and standards.

- Assist between automated robots and automated joining systems.

- Innovate with new joining concepts or designs with new products.

- They will provide a variety of joining services.

- Can provide technical joining support for the equipment.

- Learn new joining technology and understand the joining operations.

- Determine a quality assurance program for a range of the joined materials.

- Wide-ranging understanding of different manufacturing processes.

- A significant perspective of materials science and its relation to the joining process.

The advantages and disadvantages of mechanical joining.

Below, I will break down the mechanical joining advantages and disadvantages.

Advantages of Mechanical Joining:

- No fumes or toxic emissions.

- Capable of high tensile and shear strength.

- No structural thermal transformation of materials.

- Numerous choices of fastener materials.

- Flexibility of materials after joining.

- Easy to control quality.

Disadvantages of Mechanical Joining:

- Mechanical joint repair can be difficult or impossible.

- Many fasteners are patented.

- High cost of fastener.

Contract joining engineer career path.

Many engineers enjoy working as contractors because of the amount of change, one will experience working with many different types of clients. As a contract engineer, the challenge you will have is the type of rush that brings and keeps people in this type of high-stress contract work.

This kind of contract engineering job has many long days and hours on-site, but helping their clients is extremely rewarding. Each client project is different, which drives many contract engineers into this type of career path and why it is so easy to become a skilled contract joining engineer.

Determining what is best for the engineer looking to start their career path in joining engineering is always up to that individual. For example, contract engineers can afford to live a great lifestyle due to the high number of hours they will work with their high wages, but often this career requires a lot of travel, so you are away from your friends and family for long stretches at a time. If this still interests you, an engineering service platform like JOINER Services offers self-employed contract joining engineers to promote themselves and find more jobs.

Contract Joining Engineering Industries:

Below, I list the many different industries you could work as a joining engineer.

- Automotive

- Aerospace

- Agriculture

- Construction

- Defense

- Food & Beverage

- Heavy-Equipment

- Industrial

- Marine

- Manufacturing

- Tool and Die

Contracting affords joining engineers to sample many different types of industries and helps them focus on what career path interests them most. Then, once or if they decide to get out of contracting, they will be able to apply for an industry that they know they enjoy working in.

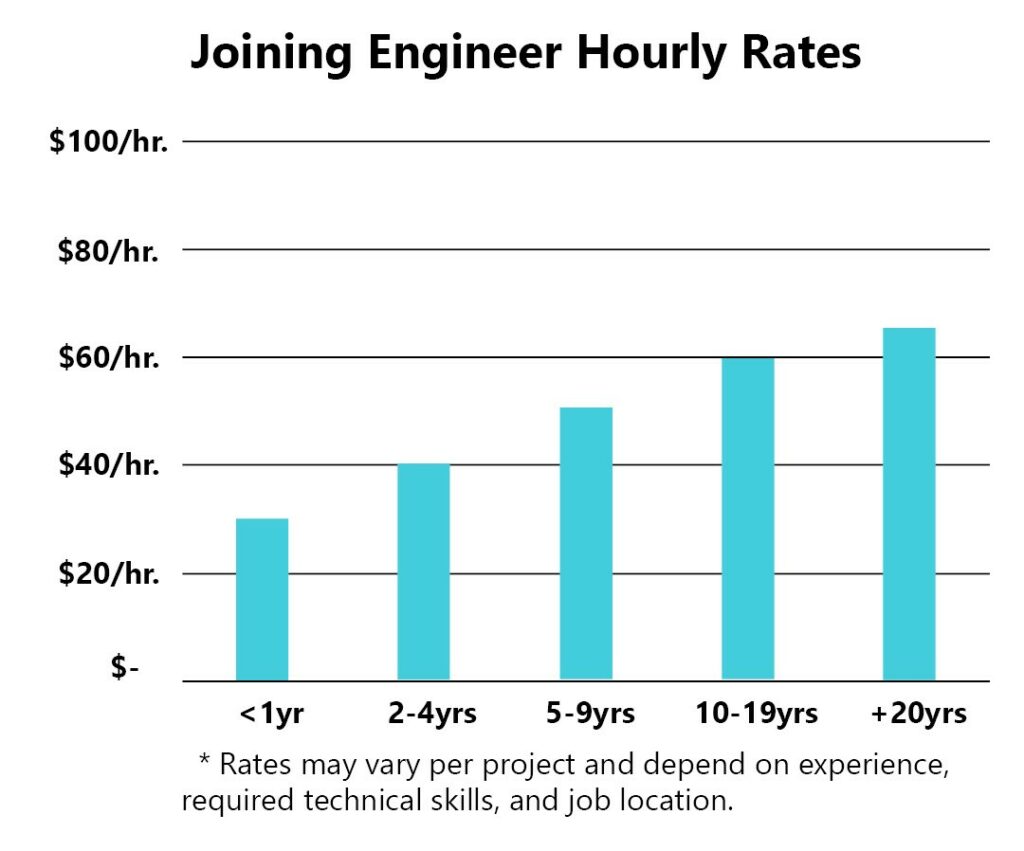

Contract Joining Engineer Salary:

According to JOINER Services data, contract joining engineers earn an average wage of $108,000 annually. If those individuals decide to become an independent contractor, they could see another 10-20% jump in annual earnings, which they could easily earn well over $130,000 annually. Performing engineering contract work sees an average annual earnings jump of 20-30% compared to a traditional W2-employed joining engineer.

Joining engineers are well-paid engineering service contractors because many have skills in industrial robot programming, which increases their hourly rate. An experienced joining engineer with a degree or certification can increase their rate even more than the average engineer.

LEARN MORE ABOUT CONTRACT JOINING ENGINEERING:

Is contract joining engineering a good career choice?

Contract joining engineering could be a great career choice for engineers interested in learning chemical joining, mechanical joining, or metallurgical joining processes. Working as an engineering contractor can also be very financially lucrative, but often, the job requires travel away from home. Some of the potential benefits of a career in contract joining engineering include the following:

- Challenging Projects: A joining engineer will see many new, exhilarating, and challenging joining applications. These engineering projects are often unique because no client project is the same as the previous job.

- Higher Wages: Joining engineers often earn a great wage as a contractor. Most earn above the average wage of a joining engineer in the United States of $108,000.

- Constantly Learning: These contract engineers gain tons of experience in the joining industry. They learn about new joining equipment, processes, systems, and applications on every single job.

- New Work Environments: As a contractor, the welding engineer will have opportunities to work in various industries. These new work environments will help develop their technical welding skills and help build their welding experiences.

A contract joining engineering can be a valuable career choice for engineers and technicians interested in the aspects of chemical, mechanical, or metallurgical processes. It is important to state that contract joining engineering is very demanding on an individual, as the job requires them to work well under client pressure while having a strong work ethic and being independent critical thinkers.

How to gain the most experience as a joining engineer?

If you want to gain the most work experience as a joining engineer, then it is important to consider these six tips are listed below:

- Pursue a degree in engineering that teaches the aspects of joining, like materials science, mechanical, metallurgical, or industrial engineering. A degree in any of these fields will give you a strong foundation of mechanical joining principles and help develop your technical joining skills for a successful career.

- For younger engineers, try getting hands-on experience through co-op programs, internships, or training programs. These can offer opportunities for on-the-job training and the chance to work with veteran joining engineers.

- Search for a job opportunity to work on various joining projects in contracting engineering. The more technical projects an engineer can experience, the more valuable they will be as a joining engineer. Contracting will also give engineers many opportunities for overtime work, giving them a higher probability of learning new technologies and equipment.

- Keep yourself informed about the latest joining processes and the fasteners used. This will help keep you relevant to industry trends and ensure that you use the most effective joining methods in the market.

- Network with other professionals in the joining industry. Attend fastening events, follow industry experts on LinkedIn, join professional joining or fastening organizations, and seek out joining engineer mentors who can provide guidance and support as you grow your career.

Companies That Manufacture Joining Technologies:

If you want to work for a company that manufactures joining fasteners and equipment, then check out the companies I have listed below:

Mechanical Joining Process Companies:

Chemical Joining Process Companies:

Metallurgical Joining or Welding Processes:

- RoMan Manufacturing

- Lincoln Electric

- Miller Welds

- ESAB

- Fronius

- Trumpf

- EB Industries

- IPG Photonics Corporation

- Amada America, Inc.