Let me start this article by saying that after I have written almost 100 blog/web pages, I don’t know why it took me so long to finally write this article: “What is weld engineering?” I graduated from Ferris State University in 2008 with a degree in Welding Engineering Technology. After graduation, I spent seven years as a contract welding engineer for two major engineering service companies. I then went to work for a company specializing in stud welding, mechanical fasteners, and self-piercing riveting. I have lived weld engineering daily for my 15-year career, so who better to write this article than me? I hope you enjoy it!

What is welding?

First, I should define the term “welding.” Merriam-Webster defines welding as “to unite (metallic parts) by heating and allowing the metals to flow together or by hammering or compressing with or without previous heating.” [1] While this statement is true, I think a more accurate definition for the context of this article would be “the joining of parts by heating the material’s surface to its melting point using a flame, electric arc, plasma, or laser and joining the materials with or without force.

What is weld engineering?

A weld engineer, or welding engineer, is an engineer who specializes in the joining of materials. They help design, implement, and improve all types of welding applications. This type of engineer deeply understands different weld processes and the unique welding techniques required to ensure repeatability required to produce quality welds. Their responsibilities often entail selecting the correct welding wires or welding rods for specific material stack-ups, managing the welding operations, troubleshooting welding issues, and staying up-to-date on the latest welding technologies and advancements in the industry.

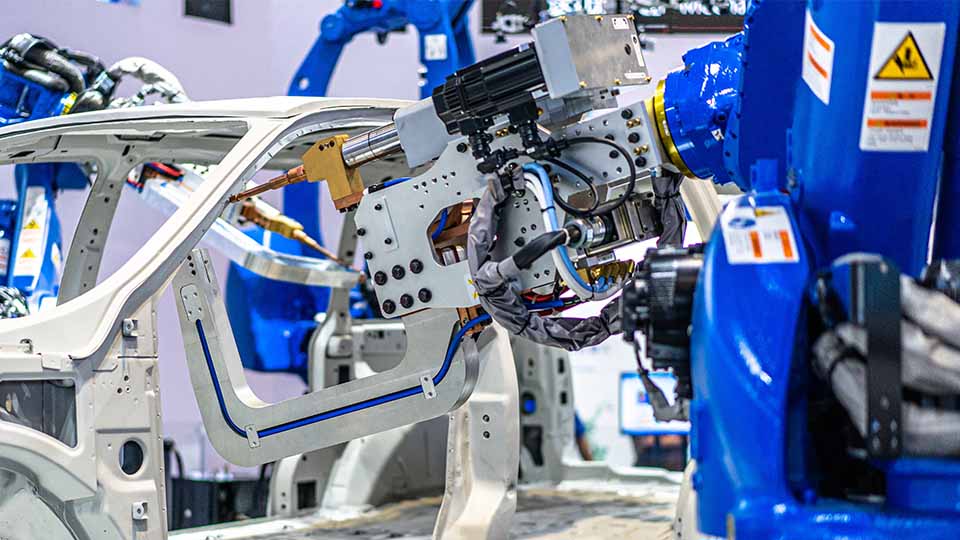

They also play a vital role in quality by developing procedure qualifications, welder qualifications, and understanding weld codes that meet welding specifications. They will help design engineers add the correct weld symbols to prints. A welding engineer will help companies improve the overall weld quality by ensuring the company follows American Welding Society standards or customer weld specifications. They will program the welding parameters on the equipment, and many can also program industrial welding robots.

What is the role of a weld engineer?

A welding engineer may be tasked in their day-to-day to do the following:

Weld Design: Identify where welding symbols should be placed on prints and determine the best welding methods based on the materials used.

Weld Optimization: Ensuring the welding processes are efficient, cost-effective, and have low scrap by creating and optimizing welding procedures.

Weld Quality: Control welding operations to ensure they meet industry, customer, and company quality and safety standards.

Weld Troubleshooting: Identify weld issues and find proper solutions to defects or failures in the welding process.

Welding Research &Development: Staying updated with the latest welding technologies and introducing innovative welding technologies when and where beneficial.

What significance do weld engineers have?

Weld engineers play a significant role in these critical areas:

Safety: These engineers ensure the structural weld integrity of products while keeping the welders safe with proper PPE, ensuring welding robots can be safely operated, and people who use the final products are free from weld failures.

Quality: They guarantee that products meet the desired specifications and are defect-free, ensuring consumer trust and brand reliability through destructive and non-destructive testing methods.

Efficiency: By optimizing welding processes, they ensure cycle time, which directly affects a company’s ability to deliver products.

Cost-Effectiveness: They can introduce methods that reduce costs, scrap, and energy consumption, making the manufacturing process more cost-effective.

Training: Weld engineers will train welders on proper torch angle and weld techniques for different weld joints.

Types of Welding Processes:

Below, I list the most common welding processes a weld engineer may encounter during their career. During my 15-year weld engineering career, I have used 12 of the 17 welding processes listed below.

1. MIG – Gas Metal Arc Welding (GMAW):

Gas Metal Arc Welding (GMAW) or Metal Inert Gas, more commonly called MIG welding, is a semi-automatic welding process where filler wire is continuously fed through the welding gun nozzle, and shielding gas protects the filler wire from the atmosphere. The filler wire is fed with a spool to act as a conductive electrode that creates an arc with the base material, melting the filler wire to generate the weld. MIG welding is the most common form of welding because it is easy for a beginner to learn quickly in only a few days.

This welding process is highly versatile and can weld an extensive list of materials that produce visually stimulating and clean-looking weld beads. MIG welding is extremely sensitive to outdoor factors like dust, rain, and wind, so it is not ideal for outdoor use.

2. Stick – Shielded Metal Arc Welding (SMAW):

Shielded Metal Arc Welding (SMAW), often called stick welding, is a very old process and is more challenging to learn than MIG welding. The filler material used during this process is a replaceable stick welding electrode. The welding electrode generates an arc at the end of the stick when it contacts the base material. The arc’s heat melts the electrode’s filler material to make the weld. A flux covers the welding electrode, which creates a shielding cloud to protect the weld zone from oxidation in the atmosphere, making it great for outdoor use. After welding, the flux cools and changes to slag, which is then chipped off.

3. TIG – Gas Tungsten Arc Welding (GTAW):

Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas, or TIG welding, uses a non-consumable tungsten electrode to create an arc. This welding process can be used with or without filler material. Depending on the welding application, the welder can choose different starting techniques to create an arc, such as using a high-frequency, scratch, or lift start. TIG welding requires a constant shielding gas supply to protect the welding atmosphere. This welding process is difficult to learn and sensitive to external elements like wind, dust, and water. This process is known for welding applications on nonferrous materials like aluminum, magnesium, and stainless steel.

4. Flux-Cored Arc Welding (FCAW):

Flux-cored arc welding (FCAW) is extremely similar to MIG welding, as the same power supply can perform both welding processes. FCAW has a flux covering the wire, creating a shielded zone from the atmosphere of the welded area, and therefore, no external shielding gas is required. This welding process is excellent for heavy plate welding; however, the flux-cored wire produces some slag that should be cleaned post-welding.

5. Submerged Arc Welding (SAW):

Submerged arc welding involves covering the welded joint with a sand-like flux that encloses the welding arc and wire. This flux barrier makes this process safer, as there are no welding fumes, infrared radiation, or visible arc. SAW is a fast welding process for thick materials requiring deep welding penetration.

6. Oxyacetylene Welding or Gas Welding:

Oxyacetylene welding is one of the hottest welding methods that is performed at 3,500 degrees Celsius. This type of welding generates heat when a mix of oxygen and acetylene gases passes through a torch. This gas welding process involves three flame types: neutral, carburizing, and oxidizing. This portable process is relatively easy to learn and can be used on different sizes of metal joints with and without filler metal.

7. Thermit Welding:

Thermit welding happens when mixing aluminum powder and iron oxide, which is then ignited. It then leads to a non-violent exothermic reaction, creating a weld. The excessive heating to 1,300 degrees Celsius liquifies the metal and then can be poured into the weld joint. The liquid metal hardens upon cooling to create a solid welded joint. This simple but fast welding process can join similar or dissimilar materials and can be done without needing a power supply.

8. Electron Beam Welding (EBW):

Electron beam welding involves firing a high-velocity electron ray at the material. The electrons’ energy will transfer to melt the base material, which will cause the parts to be welded together. The process is excellent for welding thin or dissimilar materials with different melting points. The downside of this welding process is that it must be performed in a sealed environment, so the capital cost for equipment is very high.

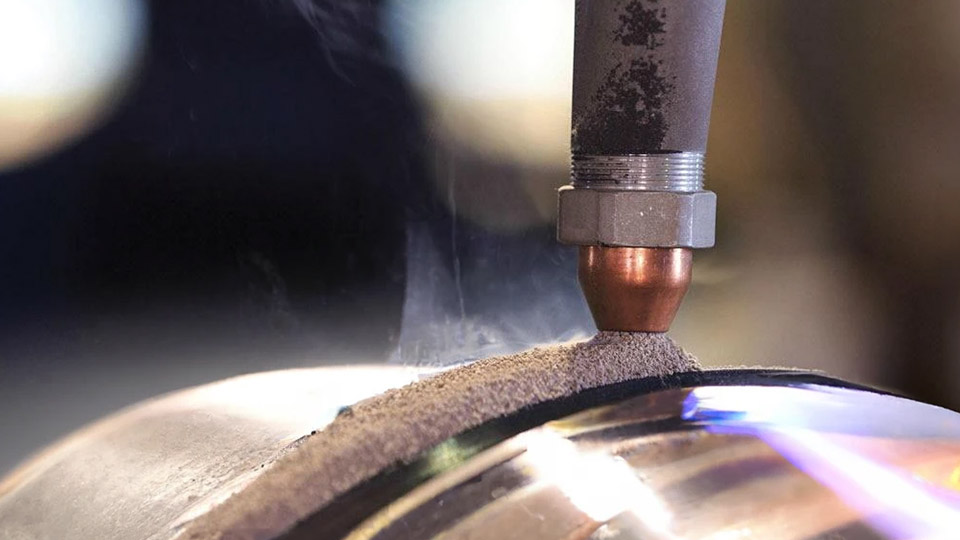

9. Plasma Arc Welding (PAW):

Plasma arc welding is very similar to TIG welding. Instead of using a tungsten torch, this process uses a plasma torch. The torch passes an electrical current through the orifice of the nozzle that is protected by gases. The plasma torch has excellent heat localization and temperature control, which is very helpful for small weld areas. It produces a thin weld bead and can be welded at high travel speeds.

Picture credit to: Linde [2]

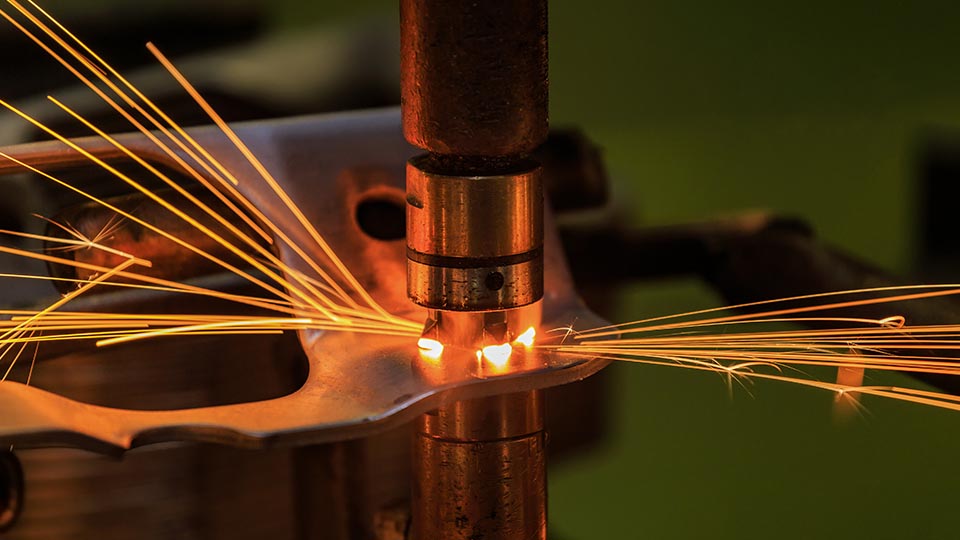

10. Resistance Spot Welding (RSW):

Resistance spot welding, often called spot welding, is a thermoelectric welding process where electric resistance creates heat, producing molten material. Then, force is used to join the materials. This welding process requires double-sided access to the welding location because of the high forces required to weld. Spot welding is an excellent process for welding thin and similar materials together. It only has two consumables: the water-cooled electrode caps at the tip where the electrode produces its heat. This differs from most welding processes because it requires no filler material.

11. Projection Welding (PW):

Like spot welding, projection welding uses resistance to create heat and high forces to join the material. This type of welding is a double-sided welding process, only this time a “projection” or “dimple” is used on one of the materials. Generally, these projections are on a nut or fastener. This welding process does not use caps but an upper and lower electrode, usually uniquely configured to match the base material and fastener.

12. Laser Beam Welding (LBW):

Laser beam welding or laser welding can be used on thermoplastics or metals. This process uses a laser as its heat source to create the welds. This process requires special eyewear and a protective booth to weld, so there can be a more significant capital cost for companies. Laser welding is an extremely fast process that can be used with or without filler material. It can weld on many different types of materials and can be easily automated with industrial robots, so it is excellent for large-volume production.

Picture credit to: Trumpf [3]

13. Electroslag (ESW):

Electroslag welding is a highly advanced welding process that joins a thin edge of two vertical metal plates. Instead of welding outside a joint, it occurs between the edges of the two metal plates. The copper electrode wire feeds through a consumable metal guide tube that acts as the filler material. Electricity is then introduced; it creates an arc, and the weld starts at the bottom of the seam and moves up slowly, creating the weld in place of the seam. This is a semi-automated process that must be performed by special welding equipment.

Picture credit to: The Fabricator [4]

14. Ultrasonic Welding (UW):

Ultrasonic welding can be used for joining plastics or metals. This type of welding equipment can be customized to fit the exact part being welded between its nest or anvil base and the sonotrode (the piece that creates ultrasonic vibrations) horn that is connected to a transducer. Welding then occurs when a low-amplitude acoustic vibration at a specific frequency depending on the materials that are being joined.

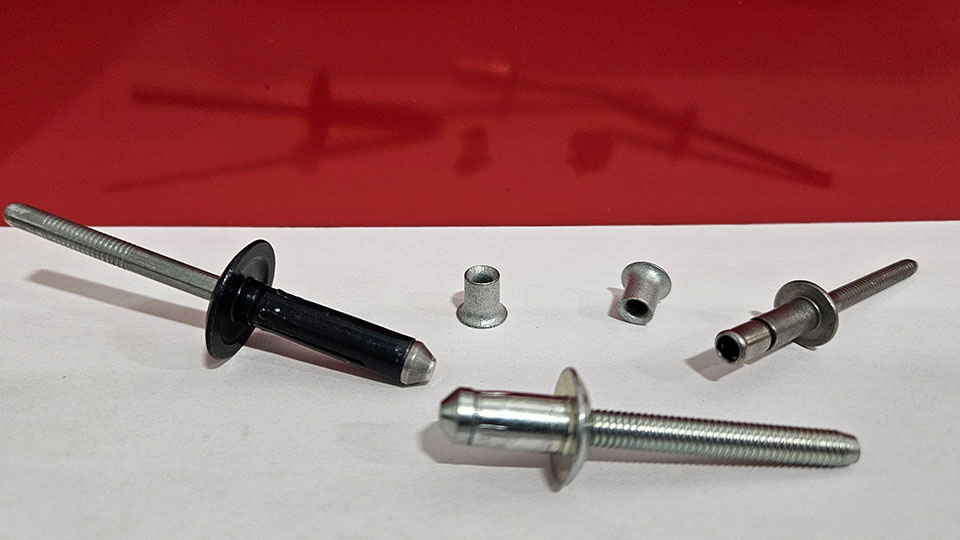

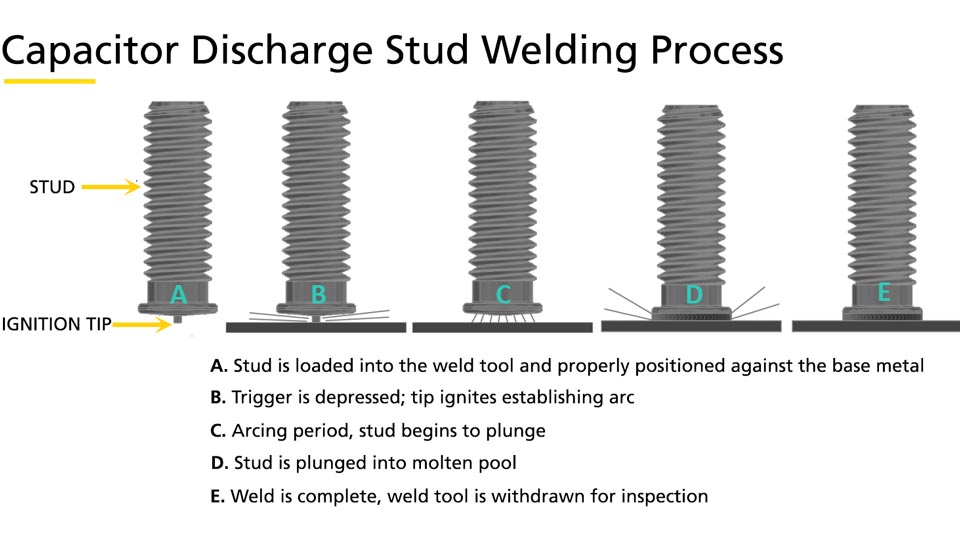

15. Capacitor Discharge (CD) Stud Welding:

Capacitor discharge stud welding or CD welding is when capacitors are charged to a preset parameter on the power supply. After the welding gun trigger is pulled, the stored energy in the capacitors is then “discharged,” and the large burst of electricity creates the molten weld pool. Then, the gun plunges the stud down into the molten weld pool. CD welding studs have a pointed tip on the weld face, called a pip, that is consumed during the welding process.

Picture credit to: Stanley Engineered Fastening [5]

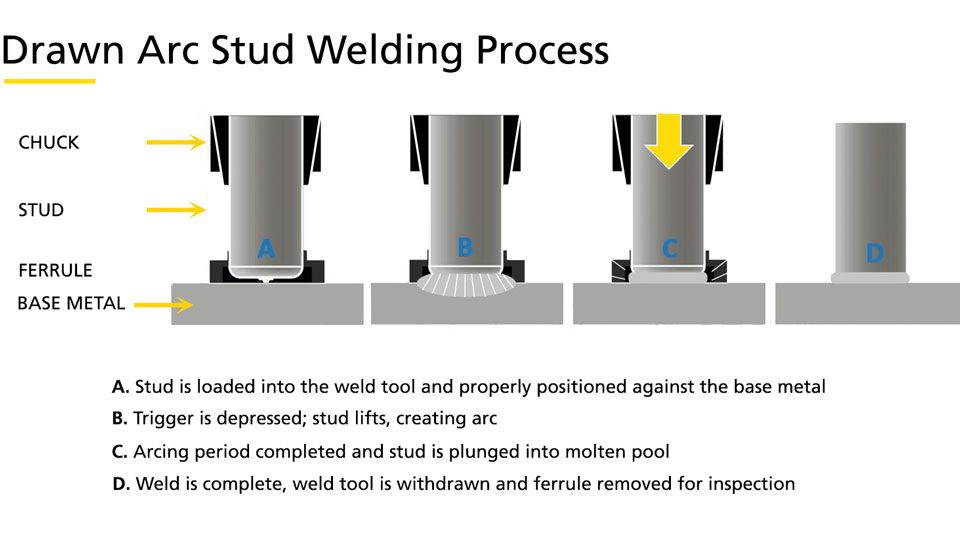

16. Drawn Arc Stud Welding (DAW):

Drawn arc stud welding is a process similar to CD stud welding. However, it does not use a pip to start the arc. An operator uses a welding gun to trigger an encoder or electric solenoid so the gun can lift the stud to a specific height off the base material. The drawn arc then melts the stud and base material, creating a molten weld pool. The gun then plunges the stud into the molten weld pool. Some studs may use ceramic ferrules to help contain the molten weld flash (fillet) from creating massive amounts of expulsion while reducing arc brightness, and the vents help expel weld gasses.

Picture credit to: Stanley Engineered Fastening [5]

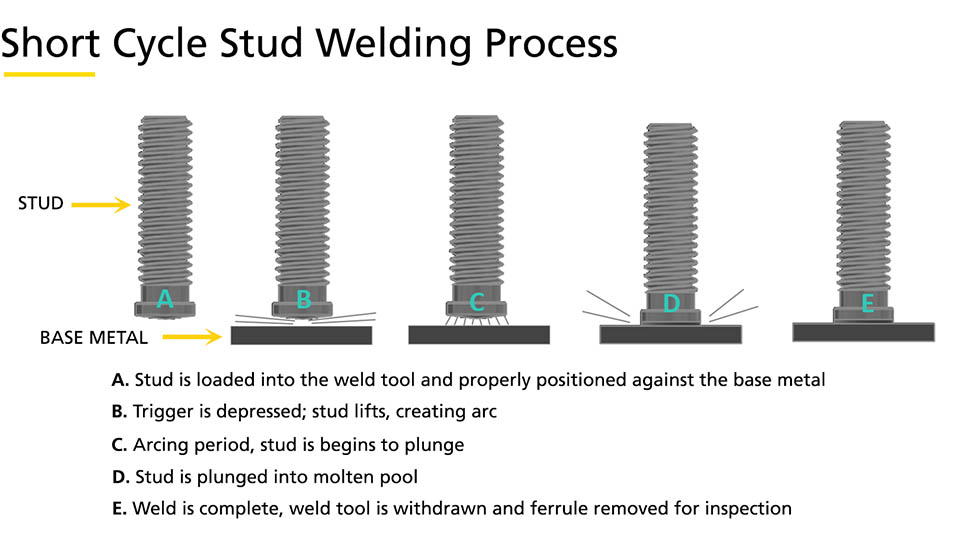

17. Short Cycle (SC) Stud Welding:

Short cycle (SC) stud welding is exactly like drawn arc stud welding, except this welding process occurs in a quicker weld time frame of only 20 ms to 30 ms. This welding process works very well on thin sheet metals and is usually for studs less than ½” in diameter.

Picture credit to: Stanley Engineered Fastening [5]

How to become a welding engineer?

To become a weld engineer, you’d first want to start with a strong educational foundation. In high school, focus on subjects like mathematics and physics and consider taking any available vocational classes related to metalwork or welding. After high school, pursue a Bachelor’s degree in Materials Science, Welding Engineering, Metallurgical Engineering, or Mechanical Engineering. This formal education will provide the theoretical background you need.

While in university or soon after, I suggest you engage in internships or co-op programs related to welding during your summers off. These opportunities offer great experience and can significantly enhance your understanding of welding processes in the real world. Once you’ve gained your degree or two years of experience, consider obtaining welding certifications from a recognized educational organization like the American Welding Society. This will not only highlight your welding expertise but also boost your employability by showing your employer you are willing to continue your education in the industry.

Given the rapid technological advancements in welding equipment, continuous learning in the welding industry is essential for a weld engineer. Attend workshops, seminars, events, and courses to stay updated with these new products. Over time, as you gain more experience and perhaps additional certifications or even a Master’s degree, you can progress to become a senior weld engineer or specialize in specific welding areas of the industry. Networking with professionals and joining welding associations can also help in career advancement and staying informed about the latest trends and technologies in welding engineering.

Welding Engineering Education:

A range of universities and colleges nationwide provide welding engineering programs. While some institutions have higher rankings than others, choosing a degree that aligns with your welding goals is crucial. Check out these fantastic welding institutes located throughout the United States:

Ferris State University – Big Rapids, Michigan

Ohio State University – Columbus, Ohio

Pennsylvania College of Technology – Williamsport, Pennsylvania

Brigham Young University – Idaho – Rexburg, Idaho

Butte College – Oroville, California

Weber State University – Ogden, Utah

LeTourneau University – Longview, Texas

Goodwin University – Hartford, Connecticut

Anoka Technical College – Anoka, Minnesota

Albany Technical College – Albany, Georgia

Weld Engineering Technical Skills:

As a weld engineer, you must be a technical expert in joining metals. However, it is critical to know these key welding areas listed below:

Welding Codes and Procedures: Welding engineers will oversee and design welded joints. They must read and interpret welding codes and specifications in order to meet quality requirements. The welding engineer will be responsible for writing the welding procedures for any welding process. These procedures include welding procedure specifications (WPS), procedure qualification records (PQR), or welding procedure qualification records (WPQR).

Filler Metal Selection: As a welding engineer, knowing what filler metals should be used in each application is critical. The welding engineer is responsible for understanding the welding position, shielding gas, base material, heat treatment, welding code, or specification to determine the best filler material for the welding process. Depending on the welding technology or application used, the thickness of the filler metal is also a significant factor that a welding engineer should be able to identify.

Programming Welding Equipment: A welding engineer must know how to operate and program each unique welding system’s basic weld parameter settings. Knowing how to adjust the minor and main welding functions is critical. The main welding functions are the welding current, voltage, and travel speed. Secondary welding functions to program could be torch angle, welding joint position, shielding gas, welding technique, arc length, and pulsing parameters.

Weld Quality: A welding engineer will perform quality checks on welds by either non-destructive or destructive welding inspection methods. A certified welding inspector will verify the welding operation during the manufacturing process. Weld engineers are often responsible for creating welding documentation that meets weld quality standards, like procedure qualification record (PQR) or welding procedure specification (WPS) sheets. Documentation control is critical to a welding engineer because of the potential consequences of a weld failure.

Welder Training: As a welding engineer, you may be asked to perform manual welding training for welders, technicians, maintenance, or engineering staff. You may also be asked to perform training on welding equipment, welding processes, or different welding applications. To qualify manual welders, only a certified welding inspector or engineer can qualify the welder, not a weld technician or engineer.

Weld Equipment: Welding equipment requires maintenance and replacing welding consumables as they wear. They may even be asked to perform repairs to welding equipment. A welding engineer must also identify the right welding equipment for the job, so they produce the most efficient weld possible.

Weld Processes: Weld engineers will learn many different welding processes throughout their careers. Some welding processes are relatively similar, like submerged arc welding, metal inert gas, and flux-core arc welding, all use a filler wire fed by a welding gun. In contrast, other processes like resistance welding and drawn arc welding are more similar because they deal more with only current and time calculations. Many weld engineers draw on these different welding processes to help them create quality welds when working with a new weld process.

Weld Application Types: Throughout a weld engineer’s career, like welding processes, they will also most likely work with many different weld applications. These could include manual, semi-automated, fully automated, or robotic welding systems. These different welding application types work better for weld jobs. For example, an outdoor application working on oil and gas may need to be welded with shielded metal arc welding. At the same time, high-volume automotive production might use metal inert gas welding.

What soft skills must a weld engineer know?

A welding engineer must have outstanding technical welding expertise, as listed above, and some fundamental “soft” skills to help them complete any job. Below, I list a few of these essential skills.

Communication: A welding engineer must be able to communicate complex information about welding processes to both experienced engineers and other co-workers from various disciplines. When collaborating with these co-workers, the engineer must be able to easily explain issues and how the welding problems can be resolved without getting into details that may confuse people.

Problem-Solving Abilities: This is essential because unexpected issues arise often, and the weld engineer must find ways to reduce spatter, remove porosity, ensure complete fusion, and even reduce scrap. Not one single solution is always the answer, even for a weld fault that occurs regularly.

Attention To Detail: This is another vital topic for a weld engineer. During quality checks, operators, maintenance, weld technicians, or engineers can miss many weld faults. The welding engineer is responsible for finding weld failures and taking the corrective actions required to meet welding code specifications or customer welding specifications.

Continuous Learning: This is a significant necessity as a weld engineer. Schooling or education will only teach about some welding processes. It is just impossible for a welding institute to teach them all. Therefore, it is up to the weld engineer to learn new processes and learn from prior welding experiences. They must also commit to staying up-to-date with the rapidly evolving welding equipment. Learning how to program industrial robots or even PLC programming is also a great idea to further your skills and personal learning.

Writing And Documentation: A weld engineer must write and record lots of data and information throughout their welding career. They may have to write welder training programs or create welding procedures for their employer. They may also have to help write and document weld quality processes that meet the required customer quality standards.

Where do weld engineers work?

Weld engineers can work in many different industries because welding is required in many industries because of the need to join materials. Below is just a sample size of industries that require a weld engineer.

- Construction

- Engineering Services

- Automotive

- Aerospace

- Shipbuilding

- Oil and Gas

- Railroads

- Energy

- Manufacturing

- Defense

- Research and Development

- Renewable Energy

- Engineering Consulting

- Education and Training

Are you looking for a state with many of these welding job opportunities? Then check out the weld engineering jobs in Michigan.

FREQUENTLY ASKED QUESTIONS:

Below, I list some questions often asked about weld engineering:

Welding Engineer Salary:

Welding engineer salaries can vary state by state and can be influenced by several factors such as work location, type of industry, and welding process. However, the more experience an engineer has, this typically translates into a higher-paying job. Below, I list the weld engineer salary options for self-employed engineers vs. employees.

In 2022, JOINER Services reported for its U.S. self-employed contract weld engineers:

- Entry-level: $40/hour

- Intermediate: $60/hour

- Expert: $80/hour

In 2023, Zip Recruiter reported for U.S. salaried weld engineers [6]:

- Entry-level: $33/hour

- Intermediate: $39/hour

- Expert: $53/hour

Welding Engineering Career Path:

If you are looking for weld engineering jobs, the career offers:

- Job Stability: Welding is vital to so many industries, from food and beverage, medical, industrial manufacturing, aerospace, shipping, energy, construction, automotive, defense, and many more. It is hard to see a future without it.

- Ability To Travel: The job provides many of opportunities to travel for work, especially those who do contract engineering work.

- Job Growth: There are many different types of welding applications and processes to learn, so you can find a niche product and become an expert or learn many different processes and become a well-rounded engineer.

- Excellent Salary: It provides lucrative compensation, especially as fewer people enter the industrial manufacturing industry, and the demand for quality engineers will increase.

Why are weld engineers important?

Welding engineers play a critical role in ensuring the integrity and durability of metal structures, directly impacting the safety of a product. Their expertise ensures that welded processes are performed correctly, optimizing the strength and efficiency of various metal components. They drive innovation by researching and developing new welding techniques and solutions, catering to the evolving needs of many industries. Without their specialized skills, many modern infrastructural advancements and technological developments would be severely compromised in quality and safety.

What are the different types of weld failures?

Below, I list the common types of weld failures you will see throughout your welding career:

- Stress Corrosion Cracks: Usually happen when metal comes in contact with corrosive materials.

- Hydrogen Induced Cracks: This happens when the hydrogen exceeds microstructure levels and does not dissolve in the weld metal.

- In-Services Cracks: These are caused by residual stress on the hard microstructure of the heat affected zone (HAZ), which sometimes are not caused by welding but by other external factors.

- Lamellar Tearing: Will occur outside of the heat affected zone and parallel with the line of fusion.

- Brittle Fractures: Happens across its granular structure and does not stretch the metal to its yield point.

- Ductile Fractures: Occur when the material stretches to its yield point and then breaks.

- Fatigue Failures: These failures generally happen because of cyclic loading

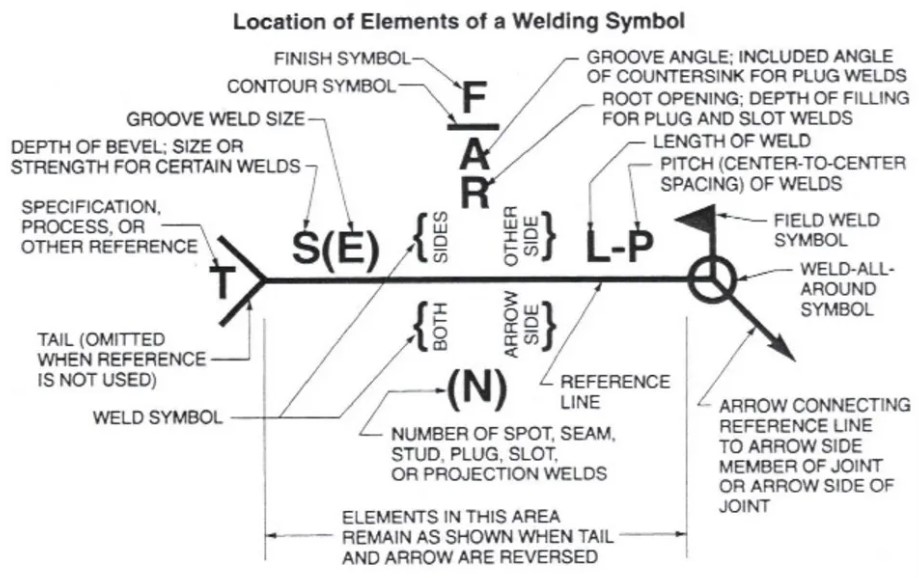

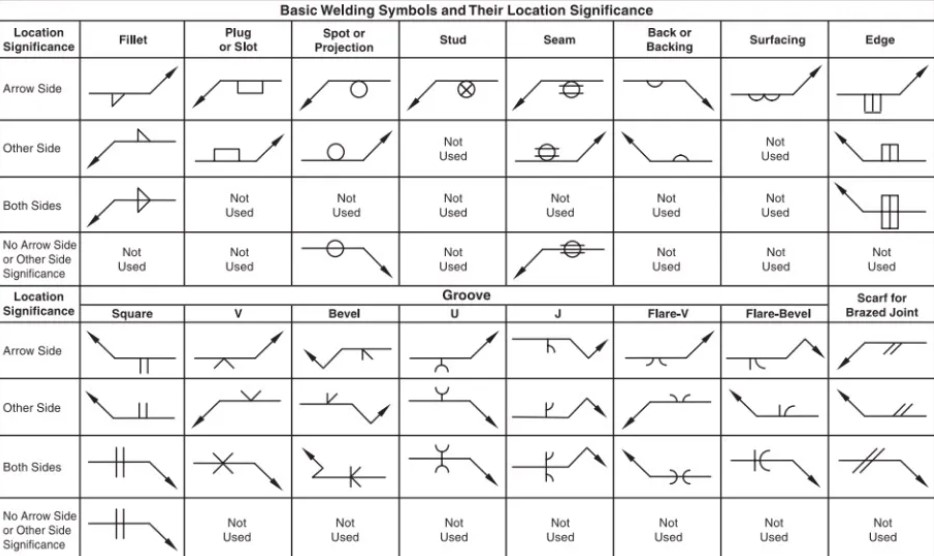

How to use welding symbols?

Welding symbols will play a vital role throughout a weld engineering career. Knowing the correct way to put welding symbols on prints and drawings is essential. This is the best way to communicate effectively with co-workers to ensure they follow the proper welding procedures. The most common standard is from the American Welding Society (AWS) on how to layout your symbols, which looks as follows:

Picture credit to: American Welding Society [7]

Picture credit to: American Welding Society [7]

Data Resources:

- [1] https://www.merriam-webster.com/dictionary/weld

- [2] https://www.linkedin.com/pulse/arcline-paw-carrying-torch-plasma-arc-welding-linde/

- [3] https://www.trumpf.com/en_US/products/machines-systems/laser-welding-systems-and-the-arc-welding-cell/trulaser-weld-5000/

- [4] https://www.thefabricator.com/tubepipejournal/article/tubepipefabrication/electroslag-cladding-for-repair-or-buildup-provides-viable-alternative#gallery-1

- [5] https://www.stanleyengineeredfastening.com/en/Resources/Stud%20Welding%20Methods

- [6] https://www.ziprecruiter.com/Salaries/Welding-Engineer-Salary

- [7] https://www.aws.org/home