Robot technician jobs in Michigan are among the most in-demand positions for industrial automation, manufacturing, and engineering services. These jobs allow people to work all over the United States and even give professional opportunities to travel the world while making an excellent salary working in this fast-paced profession.

Robot Technician Jobs:

Michigan has a large industrial manufacturing industry led by the automotive industry. As a result, it finds itself at the top of the country for robot programming jobs.

Did you know?

Types of Industrial Robots:

While searching for robot technician jobs, know what types of robots your potential future employer uses. Generally, the industrial robot type will be listed in the job description. This will help you determine which companies fit your robotic expertise to apply for.

Below is a list of robots often used in Michigan’s industrial robotic automation industry:

- Adhesive / Glue / Sealing

- Assembly

- Material Handling

- Mechanical Cutting, Deburring, or Grinding

- Painting

- Packing / Palletizing / Picking

- Welding or Joining

Brands Of Industrial Robots:

As a robot technician, you must know how to program at least one robot brand. Depending on the technician’s experience, many can program multiple brands. The most common robot brand in America is Fanuc, but below, I list some of the other most common robot brands used in the United States.

- ABB

- Comau

- Epson

- Fanuc

- Kawasaki

- KUKA

- Nachi

- Panasonic

- Staubli

- Universal Robots

- Yaskawa (Motoman)

Benefits of Robotic Programming:

- The job frequently offers the ability to learn the robotic system and robot simulation software and often work with the newest robotic programming interfaces in the industry.

- You may learn how to write code for different programming languages, depending on the types of industrial robots at your job.

- Another great benefit of being a robot programmer is that a robot programmer will stay free from many responsibilities of a regular 9-5 office job, working at a desk all day. They must be on the production floor, supporting each industrial robotic device.

- Many robot programmers enjoy the daily excitement and new challenges the job brings and adapt their skillset to future automation projects.

- The job often provides options to travel around the country or the world, especially if you do contract robot programmer work.

Robot Technician Educational Requirements:

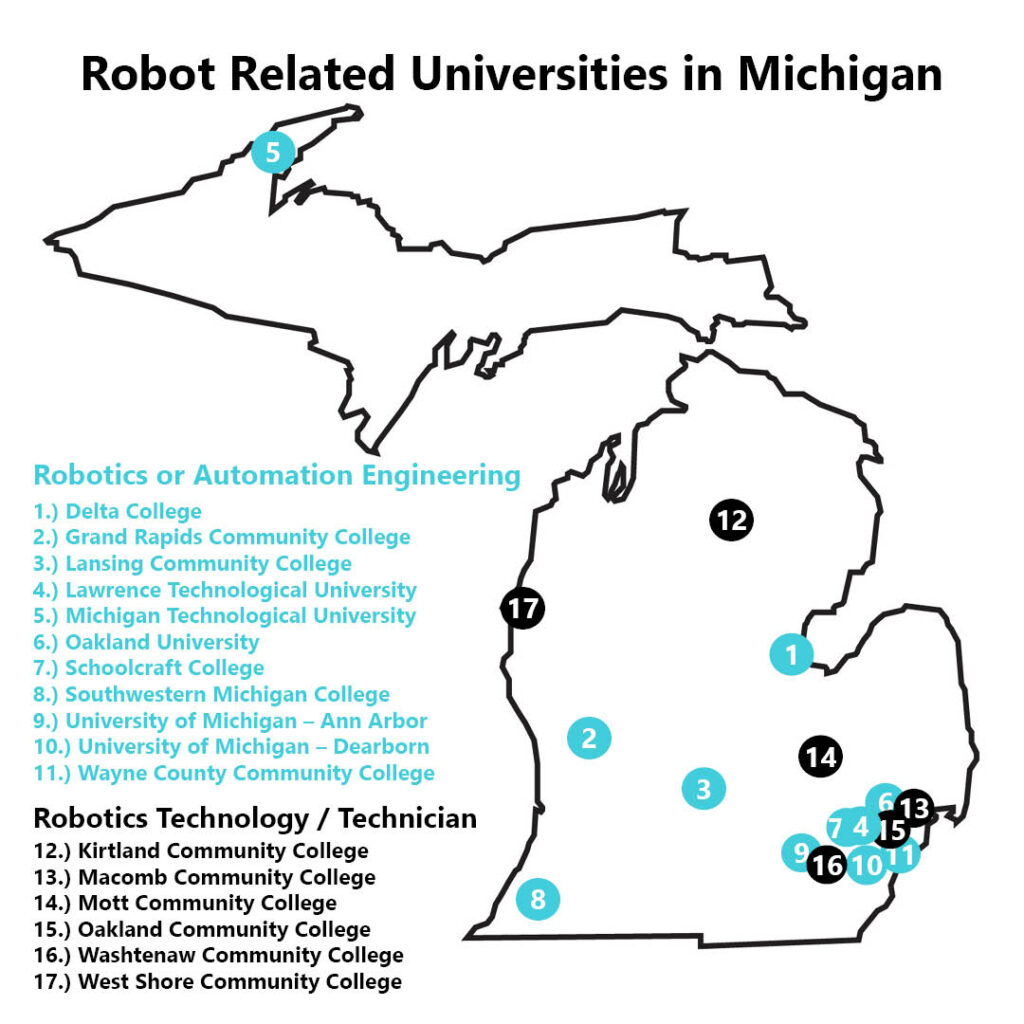

Robot technician jobs are abundant and a great career option, especially for someone looking to get into the automation industry quickly by receiving only a 2-year associate’s degree from a college or university. With an associate’s degree as a robotics engineer, automation engineer, robotics technology, computer science, or robotics technician, you could be quickly on your way to a career in the automation sector. This career has much room for growth because robot technology is constantly advancing.

The following colleges and universities in Michigan offer a major in robotics engineering, Michigan’s colleges, and universities offer a major in robotics engineering, automation engineering, robotics technology, or robot technician degrees:

Robot Programmer Training Courses:

If you are a robot technician looking to upskill your programming knowledge, then it might be a good idea to get some training. This could not only get you a bump in your salary, but having a robotic certification on your resume is a great way to show your management or future employer that you are still teachable and willing to learn more about robotics.

You can receive online robot training, but the easiest way to learn is with in-person training and your hand on a teach pendant. If you are looking for industrial automation training, then it is important to find an experienced staff and a company that provides robotic training services that have the types of robots that you are looking to get trained on.

Most training classes last 5 days and can cost upwards of $5,000; however, the information received in these robotic courses can be much more valuable to a person and company. The important part is finding time to get to the training facility without hurting production at your current place of employment.

What areas of knowledge must a robot technician know?

Below, I list the key areas of academic expertise a robot programmer must know.

- Engineering and Technology: Knowledge of the applications of practical manufacturing engineering processes. This includes applying techniques, principles, procedures, and equipment to the production and design of various automated systems.

- Electronics: The basics of chips, circuit boards, sensors, processors, electrical equipment, and components.

- Computers: Understand some robot software and other computer programs used to identify and convey messages from the robotic systems.

- Mechanical: Knowledge of fixtures, conveyors, tooling, pneumatics, and hydraulics.

- Design: Understanding essential design tools and techniques involved in automated production assembly, like drawings, blueprints, technical plans, or 3D CAD models.

- Mathematics: Basic understanding of mathematical calculations that help determine statistics, averages, and cycle time with automated applications.

- Production Process: Knowledge of materials, automation processes, quality control, budgets, and other techniques for maximizing effective manufacturing.

- Physics: Understanding the laws of physics and their relationship to each application’s fluid, material, electrical, mechanical, electrical components, and processes.

Find robot technician jobs in Michigan!

Some robotic programming jobs in Michigan require only specialized training or certifications, and others need the robot programmer only to know the robot’s operating system. Many robot programmer careers start from job shadowing other professionals or connecting within the industry. This job does not require a degree to succeed in the automation industry.

Types of robot technician jobs in Michigan:

Below, I list the many different job titles you can have as a robotic technician in Michigan.

- Robot Technician

- Robotic Weld Technician

- Robot Maintenance Technician

- Associate Robot Technician

- Robot Programmer

- Robotic Technician

- Robotic Specialist

- Automation Technician

- Robotic Field Service Technician

- Robotic Engineering Technician

What are the top skills of a robot technician?

Below are the top 8 skills robot programmers must use throughout their careers.

- Troubleshooting: Determining the causes of robotic or automation errors and deciding how to fix the issues.

- Repairing: Repairing automation machines or systems using the proper tools.

- Reading and Writing: Understanding work-related documents and relaying messages to management via email, text, or phone.

- Preventative Maintenance: Perform routine maintenance on automation equipment and determine when or what maintenance is required.

- Critical Thinking: Using reason and logic to identify key variables like the strengths and weaknesses of solutions, conclusions, or methods to problems.

- Active Listening: Giving complete attention to what co-workers are discussing, taking the time to understand the key points, asking appropriate questions, and not interrupting at the wrong times.

- Monitoring: Watching LED lights, sensors, gauges, dials, or other inputs to make sure the automation machines are working accurately.

- Resolving Issues: Identifying complex issues and reviewing linked data to develop and evaluate opportunities and implement resolutions.

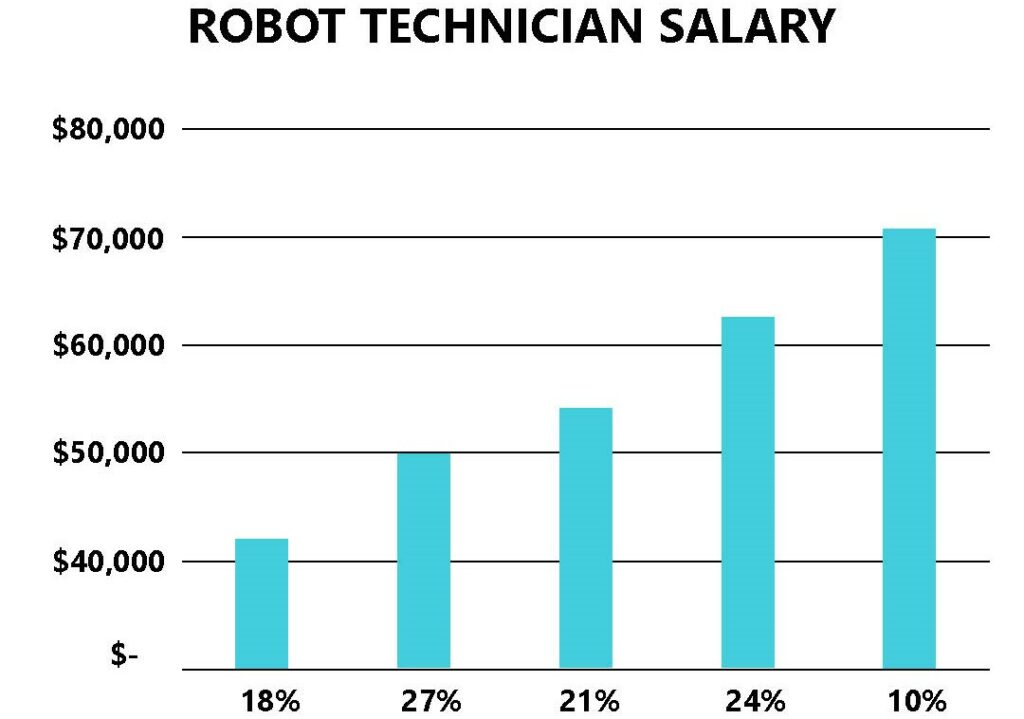

Robot technician salary in Michigan.

Robot programmers can earn a substantial salary depending on their skillset, education, certifications, and experience. Suppose you also learn how to use a programmable logic controller (PLC) from a controls engineer. You also know how to perform robot simulation, understand human-machine interface controls, or program a collaborative robot. In that case, robot programmers can easily earn well into the six-figure mark.

Below is an average expected salary for a robot technician in Michigan:

Expectations as a robot programmer.

You should be able to follow instructions and work well under stressful conditions. Often, programmers must quickly get into a robot cell, make slight robot program adjustments or touch-up points, and swiftly get out of the cell, as manufacturers want minimal downtime on any production line. Therefore, handling high-stress situations and programming speed is critical for all robot programming jobs.

A career in robot programming in Michigan

Having previous robotic programming expertise will help your chances of getting hired, as robot programming jobs are also plentiful in Michigan. These jobs pay well and include a variety of robotics programming work positions. This means that there will be plenty of job openings in Michigan because of the number of manufacturing facilities in the state.

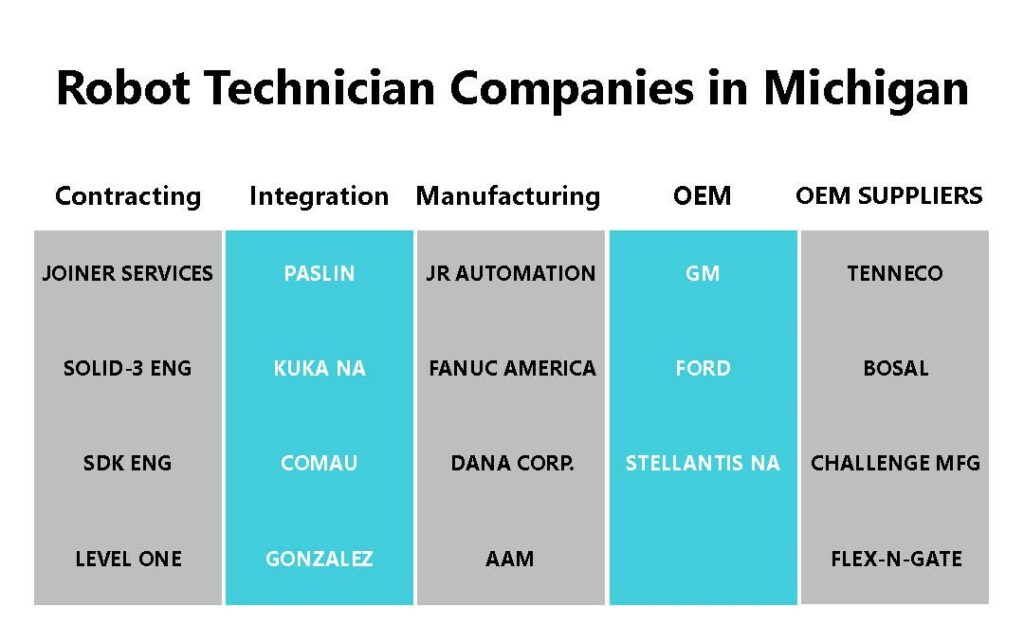

Companies often need technical expertise immediately for their robotics team, so they will hire contractors until roles can be filled. Manufacturing companies and industrial robotic integrators use engineering services platforms like JOINER Services, which use self-employed contract robot programmers. These contract robot programmers help fill temporary positions or help companies with service, system debugging, installation, assembly line support, or general engineering support.

What is the job outlook for robot technicians in Michigan?

The demand for robotics technicians is growing, and the profession expects +2,000 new jobs to be filled by 2029. Michigan currently accounts for 3% of all the robot programmers in the United States and is calculated to become 5% of the total number of robot technicians by 2029. According to College Factual, robotics engineering job openings are projected to increase by 7.1% between 2016 and 2026 [3].

Michigan companies that hire robotics technicians:

Below, I list a number of companies that use robot technicians.

Be prepared to work for your employer!

People in this profession can expect to receive much overtime work if wanted. Many other fields do not offer overtime, but because robotic programs rely on up-time, cycle-time, and run rates for production, you can see why this is allowed. Qualified robot programmers who have proven themselves at their employer can often work as much overtime as they request.

Increasing your salary can be done quickly in this field by adding only a few hours a week or working during a weekend. This fact alone makes this profession so attractive to many robot programmers.

What are the main activities of a robot programmer?

Below, I list some of the main activities a robot technician will do on the job.

- Working With Computers: Using computers and robotic software to program, write code, set up MACRO functions, enter critical data, and process information.

- Maintaining and Repairing Equipment: Calibrating, servicing, repairing, adjusting, and testing robot machines, devices, and equipment.

- Electronics: Any equipment that operates mainly with electrical or electronic components.

- Fluid Power: Adjusting and fixing any pneumatic or hydraulic systems used with the robotic machines.

- Mechanics: Any mechanical systems or equipment that operates with the robot unit.

- Process Monitoring: Monitoring and collecting the automated systems information from events, faults, or the automated systems environment, then interpreting that data to detect or anticipate problems.

- Process Control: Operate the system using controller devices or automated machines.

- Problem-Solving: Analyzing robotic data and assessing the results to select the best resolution.

- Communication: Providing information to co-workers, managers, and staff members via email, phone, or face-to-face.

Job responsibilities for a robot technician in Michigan.

Robot programmers have lots of responsibilities. Below, I list some of the top things they are responsible for in a facility.

- Installation of new robotic systems.

- Integration of older robotic equipment with new automated equipment or systems.

- Assist other engineers with the robotic systems design, configuration, or application.

- Train clients or other internal personnel on how to use the robot.

- Make repairs to the robot equipment, like replacing defective circuit boards or changing out sensors, controllers, encoders, or servo motors.

- Evaluate the proficiency and dependability of the industrial robotic system, reprogramming or calibrating the robot to maximize quality and achieve the quickest cycle time.

- Test robotic assembly performance.

- Meet internal or customer specifications.

- Develop robot test procedures and document the results.

- Maintain detailed service records of robotic or automated production systems.

- Troubleshoot robotic equipment and systems such as microprocessors, programmable logic controllers (PLCs), hydraulics, pneumatics, electronics, circuit boards, sensors, and other mechanical feedback systems.

Robot manufacturers in Michigan.

Instead of programming robots in a manufacturing plant, you want to manufacture robots as a robotics engineer. You may be surprised to learn that Michigan has a handful of robot manufacturers in the state.

Below is a list of those robot manufacturing companies:

Robot technician career path in Michigan.

Working as a robot programmer also means you may have the opportunity to advance up the corporate ladder. While working at the company, you may become a senior-level team leader and eventually manager of the robot department. This advancement means you will have more responsibilities, such as training other employees while continuing to perform at the level your company expects.

Michigan’s automation industry is growing.

In Michigan, it is easy to find robot programming jobs. All you need to do is fit the company’s qualification requirements and be a hard worker. Many robotics programmers have landed jobs working in various industrial sectors in the state of Michigan.

It is as simple as finding the right company and what type of programming interests you. If you want to quickly build a solid foundation around industrial robots, working as a contract robot programmer is for you. Check out engineering service platforms like JOINER Services to see how they can help jumpstart your career in automation.

Overview of Robot Technician jobs in Michigan:

In this article, I discussed robot technician jobs in Michigan in great detail. I wrote about the number of robot manufacturers in the state. I described basic robot job responsibilities and what will be asked of a technician.

I told you how you can build a solid career as a robot programmer and that if you’ve got a great work ethic, a job in automation can lead to a very fulfilling career. I showed how lucrative a career in robotics can be without even receiving a college degree or robot training certificate.

If you are interested in contracting as a robot technician in the state of Michigan, you can contact JOINER Services to help find you contract robot programming work.

Find robot technician jobs in Michigan with JOINER Services.

If you are a robot programmer or technician, looking for contract work in Michigan, then JOINER Services can help you find more job opportunities. Using their engineering service platform, easily search for contract projects located in Michigan or around the United States.

Join today and find a robot technician job near you!

FREQUENTLY ASKED QUESTIONS:

Below, I list some FAQs on robot technician jobs in Michigan.